Their findings were recently published in the ACS journal Energy and Fuels.

Currently, LOHCs, which work within existing retail fuel distribution infrastructure, are used to deliver hydrogen gas to refueling stations, where it is then compressed and delivered onto trucks equipped with hydrogen fuel cell or combustion engines.

This current approach incurs significant energy loss due to endothermic hydrogen release and compression at the retail station. To address this, our work is exploring a more efficient application, with LOHC-powered trucks featuring onboard dehydrogenation.

—Prof Green

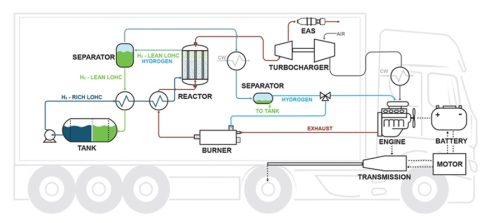

To implement such a design, the team aims to modify the truck’s powertrain to allow onboard hydrogen release from the LOHCs, using waste heat from the engine exhaust to power the dehydrogenation process.

Proposed process flow diagram for onboard dehydrogenation. Component sizes are not to scale and have been enlarged for illustrative purposes. Image courtesy of the Green Group.

The dehydrogenation process happens within a high-temperature reactor, which continually receives hydrogen-rich LOHCs from the fuel storage tank. Hydrogen released from the reactor is fed to the engine, after passing through a separator to remove any lingering LOHC. On its way to the engine, some of the hydrogen gets diverted to a burner to heat the reactor, which helps to augment the reactor heating provided by the engine exhaust gases.

The team’s paper underscores that current uses of hydrogen, including LOHC systems, to decarbonize the trucking sector have drawbacks. Regardless of technical improvements, these existing options remain prohibitively expensive due to the high cost of retail hydrogen delivery.

We present an alternative option that addresses a lot of the challenges and seems to be a viable way in which hydrogen can be used in this transportation context. Hydrogen, when used through LOHCs, has clear benefits for long-hauling, such as scalability and fast refueling time. There is also an enormous potential to improve delivery and refueling to further reduce cost, and our system is working to do that.

—Sayandeep Biswas, first author