This has been a breakthrough year for non-battery storage, with key advances in pumped hydro, power-to-gas, and thermal storage technologies. Many industry players are moving beyond pilot projects to contracted projects, which could lead to increased scale and lower costs.

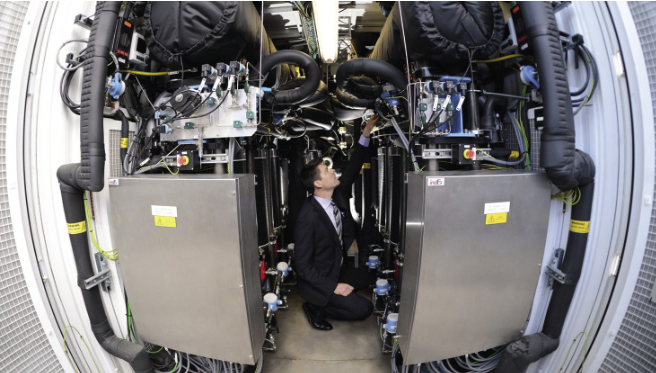

Simon Bourne, CTO of ITM Power, inside Thüga Group’s power-to-gas plant. Image: ITM Power

Simon Bourne, CTO of ITM Power, inside Thüga Group’s power-to-gas plant. Image: ITM Power

Pumped hydro storage

Pumped hydro storage, a tried-and-true technology for long-duration storage, involves using electricity to pump water to an upper reservoir from a lower reservoir or lake. When power demand is high, the water flows downhill from the upper reservoir, powering hydroelectric turbines that generate electricity.

Closed-loop pumped hydro uses two man-made reservoirs, with no connection to a natural body of water. A closed-loop system can be designed to generate power for eight to 10 hours, and to recharge by pumping water uphill for 10-14 hours, as indicated by plans for projects in Montana and Arizona.

Most of the 27 licensed pumped hydro projects in the United States, ranging across 16 states and totaling 18.8 GW, are at least 30 years old. However, there is also a robust pipeline: Preliminary permits for 20 GW of new capacity have been awarded by the Federal Energy Regulatory Commission, and applications have been submitted for another 19 GW.

There may be even more feasible pumped hydro sites in the United States, as an estimated 500,000 sites are technically suitable globally, meaning that they have potential locations for both high and low reservoirs.

Cost projections for pumped hydro are scarce, perhaps because there is only one modular component used – the reversible hydro turbines. All other costs are site-specific, from engineering and earth moving, to construction of the powerhouse containing the turbines.

One cost projection concluded that pumped hydro storage with more favorable financing is cost-competitive with lithium-ion battery storage.

Copenhagen Infrastructure Partners appears to back that assessment, given the firm’s equity investment last summer in a 400 MW pumped hydro storage project in Montana. The project has a license for construction and operation, and construction could begin next year.

Power-to-hydrogen (or other fuels)

Power-to-hydrogen is another established technology, at least for installations of modest scale. Hydrogen that is produced using electrolysis can be stored and used later to generate electricity via fuel cells. This is a potential long-duration energy storage option.

At least three small industrial installations have been announced over the past year, all using the proton exchange membrane (PEM) electrolysis technology to produce “green” hydrogen by using solar or wind power to electrolyze water into hydrogen and oxygen.The resulting hydrogen may be stored in pressurized vessels, while it awaits use in fuel cells. Because the hydrogen storage is separate from the electrolyzer units, there is no technical limit to hydrogen storage capacity for a given system of electrolyzers.

While PEM and other electrolysis technologies are well-established, achieving economies of scale is challenging. Hydrogen technology may need to expand its foothold across a range of markets, scaling up and driving costs down, before it can become a cost-competitive storage option.

That scaling-up process has begun. Last February, Hydrogenics Corp. announced plans to build a 20 MW PEM electrolyzer system in Canada for Air Liquide. At the time, the system was described as the world’s largest hydrogen electrolysis project, with an output of just under 3,000 tons of hydrogen annually.

Also last February, a framework contract for a 30 MW electrolyzer project in Switzerland was announced by a division of Norwegian-based hydrogen company Nel ASA. The project will begin with a 2 MW containerized PEM electrolyzer and will sell hydrogen to Hydrospider AG, an affiliated company of H2 Energy, for a planned fleet of fuel cell trucks.

Finally, ITM Power has announced a 10 MW PEM electrolyzer in Germany, and has a design for a 100 MW system – a size for which it reports increasing interest from potential industrial customers. ITM reports that electrolyzer costs are now under €800 per kW of capacity, and will decline to under €500 per kW by the mid-2020s.

Looking ahead, an industry and academic consortium in the Netherlands has set a goal to build a gigawatt-scale electrolysis plant. They aim to produce green hydrogen by 2025 or 2030, at a cost of about €350 million.

Another possible storage solution is to use green hydrogen to manufacture ammonia. Japan’s JGC Corp. has reported an efficient method of converting hydrogen to ammonia, which can later be combusted to generate electricity. JGC argues that this offers various advantages over hydrogen in terms of safety and cost-effectiveness.

Thermal storage

A well-known application of thermal storage is molten salt storage, typically associated with the Solana concentrating solar power plant in Arizona. The heat is used to drive a steam turbine. Yet thermal storage can involve other means of storing heat, and can also involve storing “cold.”

England-based Highview Power began operating a pilot-scale 5 MW cryogenic energy storage facility near Manchester in June 2018. The technology uses electricity to chill and liquefy air at -320˚F, store the liquid air in insulated, low-pressure tanks, and later expose the liquid air to ambient temperatures to rapidly re-gasify the air, expanding it to 700 times its liquid volume in order to provide power to turbines.

Highview Power estimates a levelized cost of $140/MWh for a 200 MW/2 GWh (10-hour) system. And similar projects are on the way. Last July, for example, Highview Power announced a contract with Nebraska-based Tenaska Power Services to help develop up to 4 GWh of cryogenic energy storage plants in the U.S. over a two-year period.

Thermal storage can be as basic as storing ice for later use in air conditioning. Instead of generating electricity, making ice can shift power demand, especially to peak solar generation hours during the summer months, with the ice later used for air conditioning.

California-based Ice Energy is currently installing 1,200 ice-energy systems under a contract with Southern California Edison (SCE). The systems will be centrally controlled to manage peak demand and load shifting.

Siemens Gamesa offers what it calls a cost-competitive technology: electric thermal energy storage. Electricity is used to heat volcanic stones in an insulated container to up to 600°C. The heat is later converted to electricity using a conventional steam turbine, achieving a 45% round-trip efficiency. The company says the technology could be used to retrofit retired fossil-fired power plants and plans to begin operation at a pilot facility later this year.

Looking ahead

The storage developments of the past year have shown that battery storage is not the only game in town. Other technologies that are capable of longer-term storage are also moving forward. Cost projections are starting to be made public, and these technologies should be gaining more attention in the year ahead.