GE is to invest up to $60m over the next decade in its existing Global Repair Service Centre in Singapore.

The company said the move underscores its “commitment to continued investments in the future of gas, which is a vital part of the energy mix”.

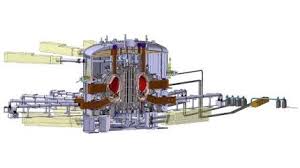

GE plans to develop next-generation repair capabilities for HA gas turbines by creating a new HA Repair and Development Centre at the site in Singapore.

The new centre will significantly increase GE’s repair development capability globally to support the industry’s most-advanced, heavy-duty gas turbine, and in turn make the site what GE calls “a world reference in power generation technology development and implementation”.

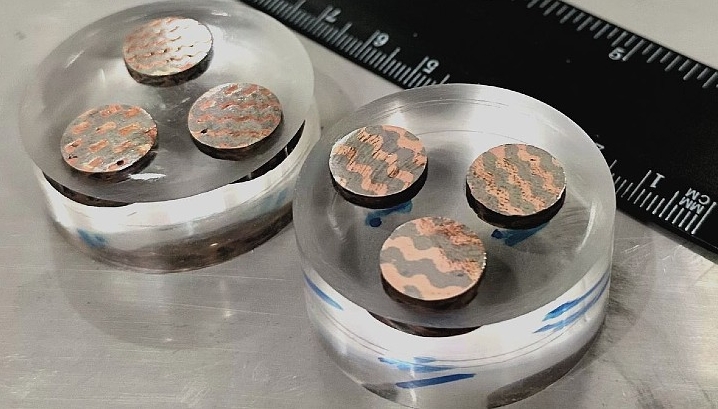

The centre will begin repairing HA components in 2021 and will include a research and development base to develop next-generation repair capabilities and the repair of high-tech components, such as nozzles and blades.

EDB, the government agency under the Ministry of Trade and Industry responsible for strategies to enhance Singapore’s position as a global center for business, innovation and talent, confirmed its collaboration and support for the growth of the new HA Center.

“GE’s investment in the Global Repair Engineering and Development Center marks the latest milestone in our longstanding partnership and extends the company’s range of activities in Singapore,” said EDB chairman Dr Beh Swan Gin. “The establishment of repair development capabilities for gas turbines is a good addition to Singapore’s base of industrial activities and also creates good jobs for Singaporeans. We look forward to the success of this centre.”

With GE’s HA fleet growing globally, the company said that its investment in Singapore is expected to add up to 160 experts in engineering and repairs and enable GE to better service HA power plant operators based in Asia, the Middle-East and all countries outside the Americas, which will be served by GE’s Manufacturing and Services facility in Greenville.

Scott Strazik, GE Gas Power chief executive, said Singapore “has been a key industrial and talent hub for GE over the last 50 years. The quality of talent, belief in our team and the work they are doing here, and our strong partnership and trust with the government and EDB are key reasons we chose Singapore for this investment.”

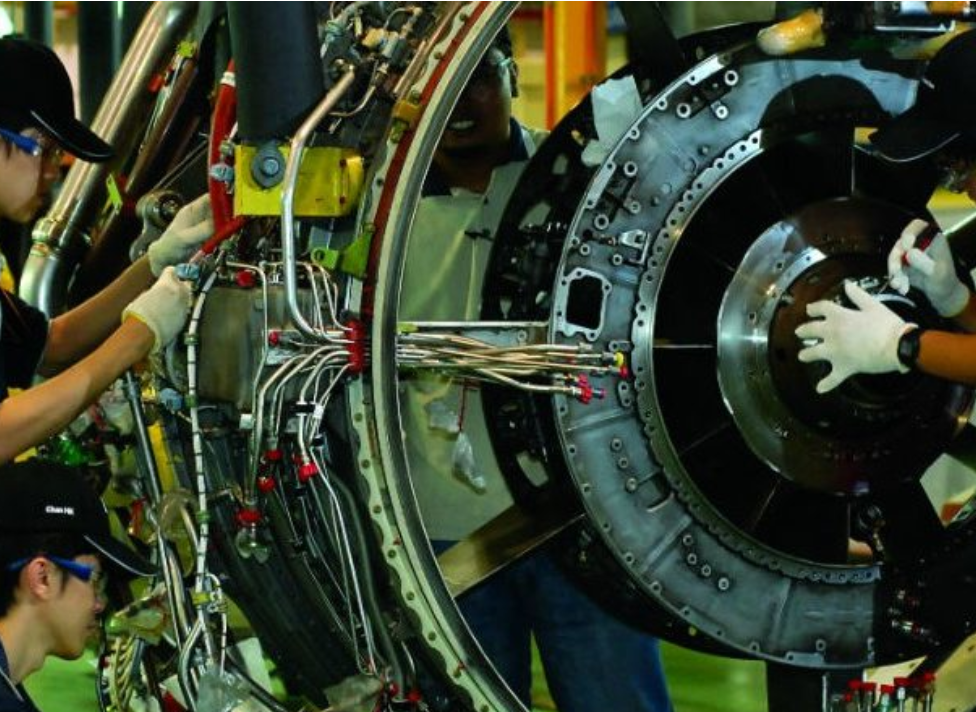

He added: “The new centre for our industry-leading HA gas turbine technology is expected to become one of the GE’s largest gas turbine repair facility globally servicing our HA and Aeroderivative gas turbines. In addition, it will allow us to better serve our HA customers in Asia as we provide localized support and expect to reduce HA repair cycle time for them by up to two months.”

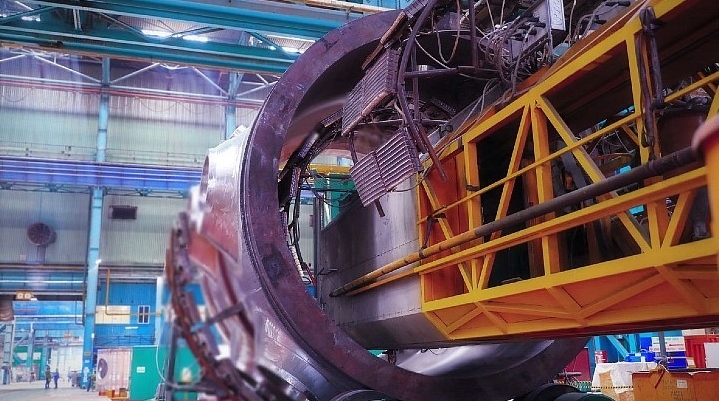

GE has been involved in the current service centre in Singapore since the 1970s in partnership with local companies. The site originally performed marine and offshore repairs.

With GE, it has evolved into power generation repairs, servicing gas turbines, steam turbines and generators. Its current focus is exclusively on power generation gas turbine repair processes and localization of GE’s newest products.

The facility carries out overhauls of gas turbine blades, rotors and aeroderivative engine components. It uses advanced repair technologies such as robotic laser cladding, adaptive CNC machining, robotic coating and polishing, and inspection technologies and has approximately 250 staff.