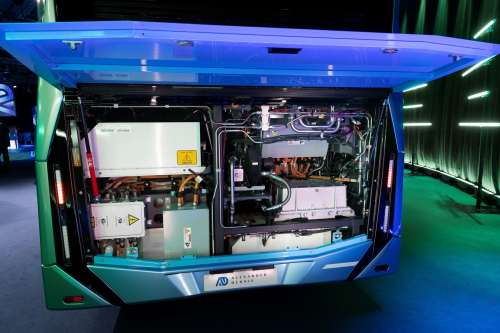

In response to our partner Alexander Dennis’s expectations, we have developed and delivered a forward-looking battery system based on the new generation of lithium-ion NMC cells. The battery dimensions allowed for their placement within the bus in a way that, for example, increased the overall passenger capacity of the Enviro400EV vehicle by 19%. Furthermore, our battery has been designed to be easily modified over time at both the package and module level, as well as individual cells. In the rapidly evolving battery technology market, we provide users with the ability to modify and incorporate newer technologies throughout the vehicle’s entire lifespan.

—Bartek Kras, Vice President of Impact’s Board

Impact's battery systems for the Enviro400EV and Enviro100EV will utilize high-strength nickel-manganese-cobalt (NMC) prismatic cells, which are less susceptible to adverse operating conditions, such as low temperatures. This technology also provides a long-term service life without initial parameter degradation.

The batteries are mounted inside the chassis and the rear of the vehicle, and under the stairs in the case of the Enviro400EV. Floor-mounted packages are mechanically isolated and not directly attached to the chassis, protecting them from external loads resulting from twisting and impacts that could cause premature damage.

The propulsion system for both vehicle models was provided by long-term partner, Voith Turbo.

If new battery sets are needed during the vehicle’s operation, they will take advantage of the advancements in the performance of subsequent generations of technological advancements without the need for vehicle modifications because package dimensions and interfaces with the vehicle are standardized.

The company is already planning the next generation of NMC batteries for Alexander Dennis, which will further extend the operational range of the next-generation Enviro100EV and Enviro400EV buses.