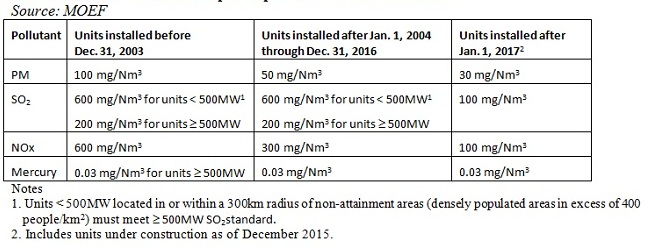

Tighter control of Sulfur Oxides (SOx), Nitrogen Oxides (NOx) and particular matter (PM) has become a priority for many countries around the world. As an example, India’s Ministry of Environment & Forest (MOEF) has issued stringent regulations that affect an estimated 140 GW of operating coal-fired power plants and all new plants built in the future. By 2022, SO2 emissions for all operating plants in India that are 500 MWe or larger must not exceed 200 mg/Nm3 and all new coal plants regardless of rating and other special category plants must meet even tighter SO2 limits of 100 mg/Nm3 (Table1). In other words, for an existing coal plant with baseline SO2 emissions ranging from 1200 – 1400 mg/ Nm3 this amounts to an 80-90% SO2 emissions reduction from uncontrolled levels.

Table.1: New Indian coal-fired power plant air emission standards

Competing FGD Technologies

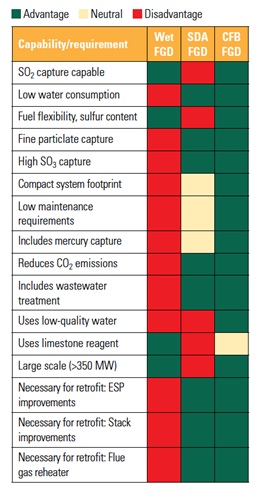

The choice of a flue gas desulfurization (FGD) system for an Indian power plant, can either be a wet, dry or semi-dry system depending on the level of SOx removal needed and the plant specifics. The conventional approach to remove SO2 from coal-fired power plant flue gases has been wet flue gas desulfurization (wFGD) technology, or, to a lesser extent, spray dryer absorber (SDA) technology. Another technology that may be better suited especially for Indian power plants is the circulating fluidized bed (CFB) technology, a dry FGD process that achieves increased SO2 removal with a much more fuel flexible treatment process that is not dependent on wet chemistry.

Each of these alternatives are discussed in the following sections and prospective owners must evaluate them with respect to their current site conditions, initial & lifecycle costs, and possible future regulation of additional pollutants.

Wet flue gas desulfurization– Until now, wFGD technology has been the incumbent FGD option selected by Indian power plants largely due to its track record on large scale units, limestone cost, and its ability to produce gypsum as a by-product for possible sale. The wFGD process uses a wet slurry produced from milled limestone mixed with water that is pumped through banks of spray headers in the absorber vessel. Flue gas enters the bottom of the absorber vessel, below the spray nozzles. The slurry droplets created by the sprays flow countercurrent to the incoming flue gas in order to mix the SO2 with the calcium-rich reagent. The resulting wet chemical reaction produces a mixture of calcium sulfite and calcium sulfate (CaSO4), also known as gypsum. A portion of the slurry is continuously removed from the absorber, collected by a separate recovery process, and then dewatered with drum or belt filters. The gypsum recovered, if not commercially recycled, must be properly and permanently stored either on-site in containment facilities or transported to an offsite location.

There are several expensive drawbacks of wFGD technology, such as process equipment that requires a large footprint near the boiler island, very high water usage to make the slurry used for sulfur removal, and significantly increased auxiliary power consumption necessary to run the wFGD. Some Indian plants that selected wFGD expecting to offset increased O&M expenses with gypsum sales have been disappointed. The quality of gypsum produced in the Indian power plant has been poor due to the low purity (<80%) of local limestone. Additionally, the Indian market for gypsum is also saturated so the expected income stream from the sale of gypsum has been replaced with a recurring expense of large-scale gypsum disposal.

The wFGD plant also requires a long-term, reliable source of high quality limestone as large quantities of limestone must be regularly delivered to the plant. Also, water usage by wFGD is 30% to 40% higher than either the SDA or dry CFB scrubber options, which poses a challenge for plants built in drier parts of India such as Rajasthan, Gujarat, Tamil Nadu where water supplies for power generation are limited. Finally, a plant with a wFGD must significantly increase operating, maintenance, and laboratory testing staff because the wFGD option is much more manpower intensive, particularly with respect to routine maintenance. For a country like India that has little to no experience with the installation, maintenance, or operation of modern air quality control systems, particularly FGD, this can be a challenge.

The wet desulfurization process also requires expensive glass or plastic liners or stainless steel for the absorber vessel, not required by the other two SO2 removal processes, which increases the capital cost, particularly for a single vessel system. The Indian power market is very price sensitive so the much higher capital cost of a wFGD compared to other technology options, remains an important evaluation factor.

Spray drier absorber. Spray drier absorber (SDA) sulfur removal systems are typically employed on plants that burn low-to medium-sulfur (<2%) coal. SDA systems generally achieve sulfur removal efficiencies in the range of 90% to 95%, depending on inlet conditions. Higher sulfur removal rates will require the addition of a fabric filter that provides for the needed reaction and mass transfer time for the sorbent and SO2 to react in a surface filter cake.

The SDA process begins with a lime sorbent, usually quicklime (CaO), that is slaked with water to form a slurry reagent. Lime is typically stored in silos much like the wFGD process. Slurry preparation can also use recycled dust from the plant’s particulate collection system to increase the solid content of the slurry to improve SO2 removal efficiency. The reagent slurry is pumped to the top of the SDA absorber vessel and is led through one or more high-speed spinning wheels within rotary atomizers located at the top of the absorber vessel to produce a spray cloud of reagent. The flue gas mixes with the spray cloud and the sorbent reacts with SO2 and SO3 to form calcium sulfite and calcium sulfate while simultaneously cooling the flue gas. The cooled flue gas leaves the absorber and enters the particulate collection system, such as a fabric filter or electrostatic precipitator.

Circulating fluidized bed scrubber. The circulating fluidized bed (CFB) scrubber is growing in popularity with plants up to approximately 600MW. Indian plant owners who are highly sensitive to the construction cost will be pleased to learn that the CFB scrubber has an installed cost approximately 60% of a similarly sized wFGD system. In India, the average installed cost of a wFGD system has averaged $65/kW, this would translate into immediate savings of almost $25/kW in favor of a CFB scrubber.

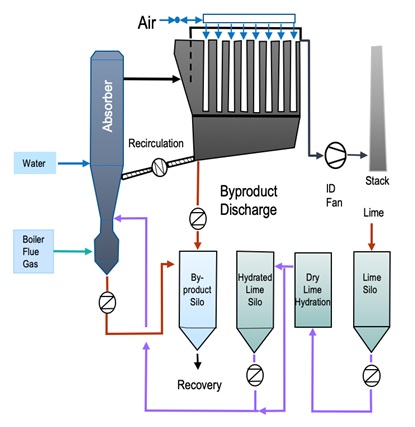

The operating essentials of the CFB scrubber and its up flow absorber are substantially different from the SDA process (Figure 1). Flue gas with fly ash enters the bottom of the absorber, flowing upward through multiple venturis to accelerate the gas causing turbulent flow.There is no need for external lime preparation so all the slurry mixing and handling equipment are eliminated. Instead, dry hydrated lime, Ca(OH)2, is directly injected into the CFB absorber along with the boiler flue gas and fly ash. An optional dry lime hydrator produces hydrated lime on-site from lower cost quick lime.

Figure 1. The CFB dry desulfurization process. Source: Sumitomo SHI FW

Recycled solids, reagents, and water mix with the turbulent flue gas providing gas cooling, reactivation of ash, and capture of pollutants.In short, unlike the other technologies, the sulfur removal process in a CFB scrubber is independent of water usage.

The design of the absorber produces high turbulent mixing of the flue gas, solids, and water to achieve high capture efficiency of the vapor phase acid gases and metals contained within the flue gas, unlike the wFGD or SDA processes.The gas and solids enter the fabric filter where solids are captured and recycled back to the absorber to capture more pollutants. Unique to the CFB scrubber, reactive absorbents, such as sodium carbonates, hydrated lime, and activated carbon, may be added to target specific pollutants such as acid gases and organic compounds for capture first within the CFB absorber vessel and then again in the fabric filter as the flue gas passes through the filter cake.

There are other important cost advantages with the CFB scrubber. Because there are no high-speed rotary atomizers within the absorber requiring a high frequency of maintenance since they are prone to erosion, scale formation, and plugging or lime slurry preparation equipment in a CFB scrubber so annual maintenance is reduced by a factor of four compared to the SDA and even more compared to the wFGD.

CFB scrubber systems have been employed at plants worldwide firing coal with a wide range in sulfur levels with no technical limit on the entering fuel sulfur content, unlike the alternative technologies discussed above. Fuel ash content seen in Indian fuels, up to 40-45%, is perfectly acceptable to a CFB scrubber. Also, the flue gas temperature does not limit the amount of lime injection as it does when using an SDA.

Figure 2. The advantages and disadvantages of the three desulfurization technologies of interest to the Indian power market are summarized. Source: Sumitomo SHI FW

This feature allows for a significant increase in acid gas scrubbing performance, should future air emissions regulations require. This fuel flexibility is an important performance characteristic for those plants receiving coal from mines with poor coal quality and reduce or eliminate the need to burn imported coal.

Sulfur dioxide removal efficiency has been demonstrated in excess of 95% (see below case study) and up to 99% depending on the entering SO2 loading. Also, unlike wFGD, CFB absorbers can be designed to remove 99% of the SO3 because of the lime reagent’s has a high affinity for SO3. Other important design features and operating advantages of the CFB scrubber that should be of interest to the Indian power market are shown in Figure 2.

CFB Scrubber Case Study

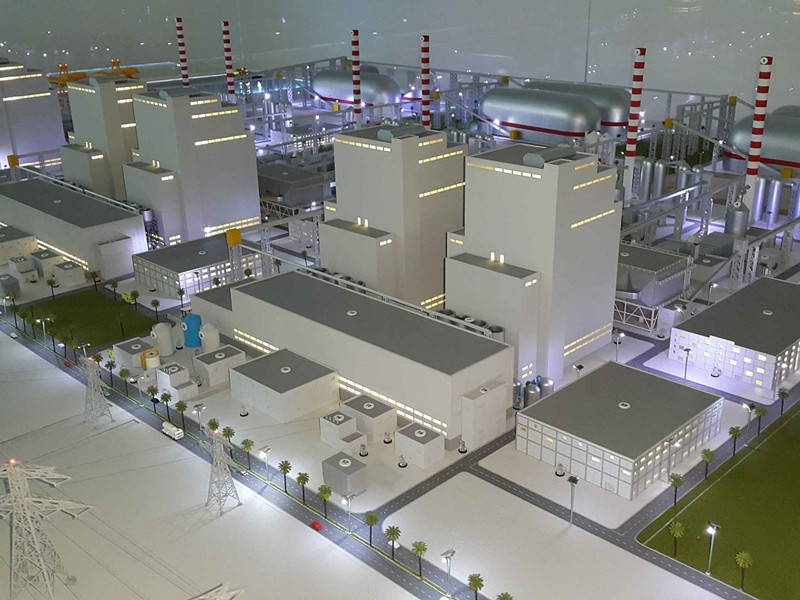

Basin Electric’s 420 MW (520 MWe equivalent at sea level altitude) Dry Fork station, located in Gillette, Wyoming, entered commercial service in June 2011 (Figure 3). Behind its pulverized coal boiler sits the largest single absorber dry scrubber operating in the world today.

Figure 3. Basin Electric Dry Fork Unit 1 commissioned by SFW is the largest CFB scrubber in the world with a plant electrical output of 420 MWe or 520 MWe at SL (Courtesy Basin Electric Co-Op and Wyoming Municipal Power Agency)

The Sumitomo SHI FW CFB scrubber has demonstrated a very high 98% availability while meeting all the strict emission requirements set by the U.S. Environmental Protection Agency and the state of Wyoming. The emission regulations are designed to directly or indirectly limit a broad array of compounds designated as pollutants, such as SO2, SO3, HCl, H2SO4, HF, PM10, PM2.5, mercury, and other heavy metals.

Since it went into operation, the CFB scrubber at the Basin Electric plant has exceeded its design performance reducing SOx by 95% – 98% to levels below 50-60mg/Nm³. It also passed a 30-day mercury removal compliance test by meeting the permitted emission limit of 2.35µg/m3 while demonstrating an Hg removal rate in excess of 95%.

Make the Right Choice

For many plants in the Indian power market, the CFB scrubber is a compelling economic choice particularly for units rated at 600MW or less due to its lower installed cost, auxiliary power and water usage. CFB scrubbers also offer a compact footprint and low maintenance while maintaining high reliability. It’s a hard-learned truth that the number of regulated pollutants will increase in the future, particularly in developing countries, so multi-pollutant control capability should be included up front rather as an expensive afterthought. Also, the fuel flexible CFB scrubber allows Indian power plants to purchase lower-cost opportunity fuels, mixes of local fuels,. For the Indian power market, 2022 is coming quickly and purchase decisions must be made very soon. Given these important characteristics, the CFB scrubber enjoys distinct and quantifiable advantages over competitive FGD processes.

Sumitomo SHI FW: CFBS vs Wet FGD Lifecycle Cost Comparison

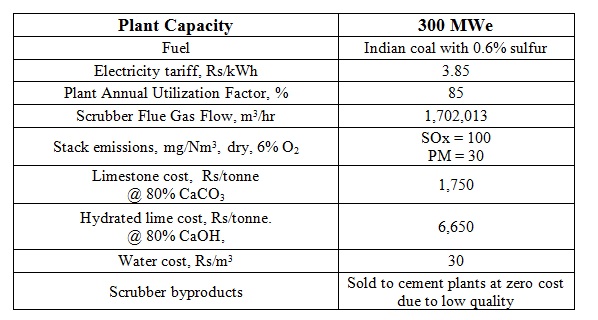

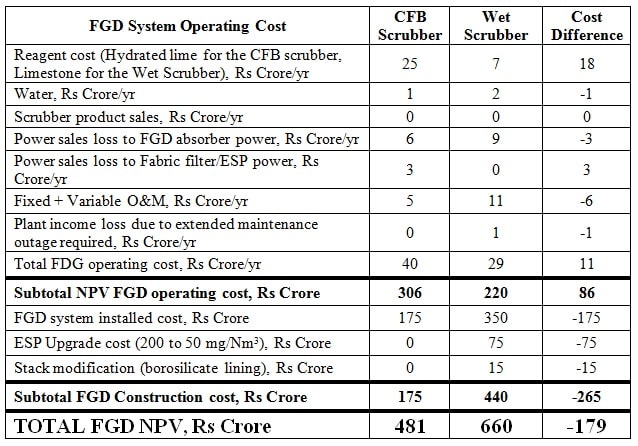

Up until now the technical advantages of the CFB scrubber for reducing coal-fired power plant emissions have been demonstrated to be superior to conventional wFGD and SDA technologies. However, for most applications the life cycle cost of the FGD installation will govern purchasing decisions. The following analysis in Table 1-3 compares the lifecycle costs between a wFGD and a CFB scrubber on a typical 300 MWe pulverized coal (PC) power plant retrofit located in India required to achieve stack emission limits of 100 mg/nm3 for SOx and 30 mg/nm3 for particulate matter by 2022.Table 1 presents the assumptions of material cost and actual plant operating factors used in this analysis.

Table 1. Operating and purchased material costs for a typical 300 MWe PC plant located in India. These material costs will be used to determine the operating costs of CFB scrubber and wFGD systems. Source: Sumitomo SHI FW

The 300 MW power plant operates at a 85% capacity factor utilizing a 0.6% sulfur Indian coal and has a long-term off-take power purchase agreement yielding Rs 3.85/kWh. Note that the purity of the limestone and hydrated lime is conservatively assumed to be 80%, below the 90% purity threshold required to produce saleable quality scrubber by products and gypsum. Thus, no value is assigned to the possible sale of the scrubber waste product nor is a cost of disposal included, which will be the case for most FGD projects in India.

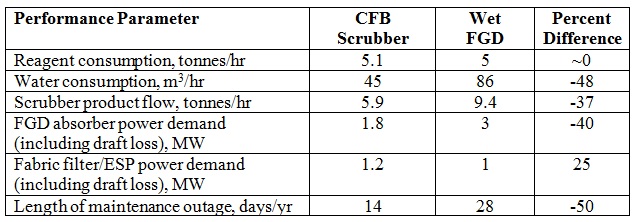

Table 2 quantifies the various consumption, effluent handling and auxiliary power requirements of the two options. Both FGD options will consume approximately the same amount of reagent (i.e. lime or limestone) largely due to similar amounts of sulfur emissions reduced and similar calcium oxide purity for both reagents. The wet FGD system has a higher water consumption by almost 50%. Note the much higher scrubber product output flow necessarily follows the much higher water consumption of the wFGD option. The auxiliary power consumption for the FGD absorber was lower for the CFB scrubber by almost 40% and 25% higher for the particulate control device such as a Fabric Filter. The net auxiliary power savings with a CFB scrubber on this unit is about 15%.

The CFB scrubber option is expected to require only a two-week annual maintenance period, normally scheduled during the annual boiler repair outage. The wFGD option will require a lengthier outage, almost twice the time given its design and operation regime, which reduces the amount of net energy the plant may supply to the grid. In India, this is vital as electricity-supply shortfall is about 20 percent during peak demand hours and lengthier outages can result in revenue loss and add to critical electricity supply disruptions.

Table 2. CFB scrubber vs. wet FGD operating conditions comparison. Source: Sumitomo SHI FW

Table 3. Results of the economic analysis based on the assumptions noted in Tables 1 and 2. The NPV is calculated based on 15 years at a discount rate of 10%.The CFB scrubber uses hydrated lime while the wFGD system uses limestone, thus the higher reagent cost for the CFB scrubber option. However, the extended maintenance period required for the wFGD penalizes the plant in lost power sales and increased maintenance cost. Source: Sumitomo SHI FW

An economic analysis of the two FGD options may now be conducted based on the plant operating assumptions found in Table 1 and the FGD operating profiles identified in Table 2. The results of this analysis is summarized in Table 3. Note, the CFB scrubber has a NPV disadvantage of Rs. 86 Crore over the 15-year analysis period for its higher operating costs, primarily due to higher lime costs, However, the CFB scrubber has a whopping Rs. 265 Crore advantage over the wFGD option in capital & installation cost. The CFB scrubber is 50% cheaper than a wFGD system in terms of initial capital cost which is a Rs. 175 crore savings for this particular plant and requires less water by almost 50%. In addition, no stack modifications are required for a CFB dry scrubber which is a Rs 15 crore savings or expensive ESP upgrades which are required with a wFGD system for many old Indian plants to meet stringent PM limits of 50 mg/nm3.

In sum, due to these value points the CFB scrubber has a NPV cost advantage of approximately Rs 179 Crore when evaluated over the lifecycle of the plant operation. Not included in this analysis are additional possible savings accruing to the CFB scrubber for a much shorter construction schedule, faster startup, shorter operator training period, and reduced inventory of maintenance parts required.

Sumitomo SHI FW

Company Logo

Company Logo Sumitomo SHI FW (SFW) is a premier global supplier of CFB Boiler technology. SFW has supplied a full range of CFB boilers totaling 36 GWe in power capacity and 30 million hours of operational experience. SFW is also a premier supplier of innovative circulating fluidized bed scrubber technologies (semi-dry FGD) for coal fired power plants for low-cost SO2 emission control.