Cobalt and nickel are widely used to stabilize the cathodes of lithium-ion batteries. However, cobalt is a rare metal, and there are potential issues in cost stability and supply-chain reliability. There are also concerns with nickel, as increased demand in recent years has pushed up market prices. Toshiba’s new lithium-ion battery cathode is free of cobalt and contains less nickel, making it a superior solution in terms of cost and resource conservation.

Use of a 5V-class, high potential cathode in lithium-ion batteries will increase cell voltage and power performance, but its development has been held back by a practical problem: a side reaction that causes electrolyte decomposition and the generation of gas that degrades battery performance. Toshiba’s new cathode significantly suppresses gas generation when used with a conventional high conductivity electrolyte.

Toshiba has prototyped a pouch lithium-ion battery that combines its new cathode with a niobium titanium oxide (NTO) anode.

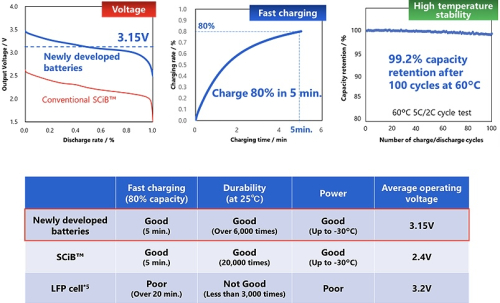

In tests, the battery demonstrates a high voltage of more than 3V, fast charging to 80% of capacity in 5 minutes, high power performance, and excellent lifetime characteristics, even at a temperature of 60 °C. Target applications for the battery range from power tools and industrial application that require high voltage with a small battery pack, up to electric vehicles.

Toshiba is presenting the cathode technology at The 64th Battery Symposium of Japan, which will be held at the Osaka International Convention Center, 28 to 30 November 2023.

The drive for a carbon-neutral future is increasing demand for lithium-ion batteries in a wide range of applications. Today’s batteries typically use cobalt as a stabilizer in the cathode, but it is a rare metal and there are concerns about sources of supply and stable supply, cost fluctuations, plus environmental issues related to soil and water pollution, and the loss of biodiversity that accompany cobalt mining and refining.

Nickel is also widely used in cathodes to help increase the energy density of lithium-ion batteries, but the refining process is unevenly distributed among certain countries. Continued progress and risk reduction in the supply chain will require batteries that do not rely on rare metals, that support resource conservation, and that use materials in plentiful supply.

In the automotive industry, one of the main markets for lithium-ion batteries, efforts are underway to increase battery pack voltages, a move that will shorten charging times, in order to improve the efficiency of on-board electronics, including the motor and inverter, and to increase battery output. Higher voltage battery cells will cut the number of cell stacks required in battery modules and lower costs.

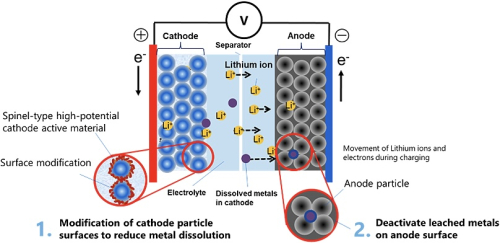

Nickel manganese oxide (LNMO), a spinel-type metal oxide, realizes a high-potential cathode that is cobalt-free with low nickel content, which is seen as a strong candidate for a future cathode in lithium-ion batteries. However, LNMO’s high working potential oxidizes battery electrolyte, decomposing it into gas, which produces significant battery swelling and shortens service life.

There are many reports of attempts to improve electrolyte oxidation resistance by increasing electrolyte concentrations, and using fluorinated solvents and ionic liquids, but this approach comes with a trade-off between suppressed gas generation and the conductivity of the lithium ions. Practical application has faced many cost and performance issues.

Toshiba’s research found that electrolyte decomposes on the surface of a high-potential cathode and generates gas, and that the metal component of the cathode material dissolves and deposits on the surface of the anode. The company used these findings to develop a technology that modifies the surface of cathode particles, effectively suppressing the reaction with the electrolyte. It also developed a technology that deactivates the transferred ions on the anode surface. In combination, these technologies successfully suppress gas generation, even with a conventional high conductivity electrolyte.

Toshiba evaluated the new technology with a prototype 1.5Ah-class pouch battery with an NTO anode. Tests of the battery found a high voltage of 3V or higher, fast charging to 80% capacity in 5 minutes, durability that maintained 80% or above of initial capacity after over 6000 charge/discharge cycles, and excellent lifetime characteristics even at a high temperature of 60 °C.

In considering potential applications of the new battery, Toshiba is looking at first using it in power tools, industrial equipment, and other applications where small size and high voltage is at a premium. Beyond that, the company aims to develop larger modules for in-vehicle applications. Going forward, the company will continue to improve the technology toward commercialization in 2028.