The first milestone in building the SHIP system was reached in September 2017, when Kyotherm entered into a binding agreement with Malteries Franco-Suisses for the sale of heat at a set price of 26 EUR/MWh plus inflation over 20 years. “We agreed with our client on a heat price even before we put construction out to tender, so we took the risk for this first SHIP plant,” Susplugas said during his conference presentation. The agreed heat price is 20 % lower than the average price that the client used to pay for gas. The system has been competitive thanks to a grant by Ademe, France’s national energy agency. The subsidy, which covers 60 % of CAPEX, is equivalent to 20 EUR/MWh over 20 years. “This is a lot less than what you could have received for a PV system via the feed-in tariff in early 2006, when people were paid between 126 and 600 EUR/MWh,” he added.

|

Field size of water-driven collectors |

14,252 m² |

|

Size of solar storage tank |

3,000 m3 |

|

CAPEX, including solar field, storage tank and integration into factory’s hot air system |

EUR 5.8 million |

|

Specific costs of solar plant |

400 EUR/m² |

|

Financing structure |

10 % equity when construction starts, bank refinancing at a later stage |

|

Ademe grant |

60 % of CAPEX, which corresponds to 20 EUR/MWh over 20 years |

|

Annual heat demand from malt business |

80 GWh as hot air between 50 °C and 85 °C |

|

Expected solar yield |

8 to 9 GWh |

|

Specific solar yield |

561 to 632 kWh/m² |

|

Heat price agreed with client |

26 EUR/MWh plus inflation over 20 years |

|

Commissioning scheduled for |

May 2020 |

Key figures on SHIP plant to be put up at Malteries Franco-Suisses in central France

Source: Kyotherm

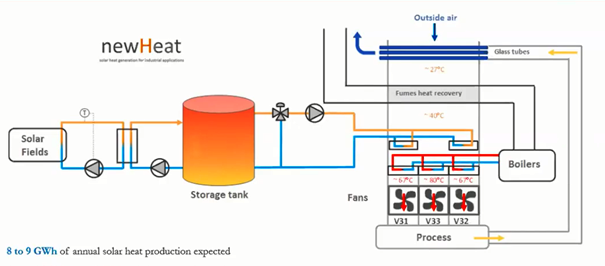

Kyotherm cooperates with French-based company NewHeat, which designed the SHIP plant, is overseeing its installation and will be responsible for O&M after commissioning. Susplugas underlined how difficult it is to find one EPC contractor for the entire solar plant (EPC stands for Engineering, Procurement and Construction). Integrating the hydraulic components of the water-driven solar field into the air-powered malt drying system of the factory seemed particularly challenging. Consequently, Kyotherm signed technology supply contracts with four companies. One of them is Savosolar, based in Finland, which delivers the field, while Sunoptimo, based in Belgium, is responsible for the integration of the solar heat into the factory by using water-to-air heat exchangers. In addition, French-based Dalkia provides the heat delivery loop, Eiffage, also based in France, delivers the storage tank and NewHeat controls and monitors the system.

Commissioning of the installation is scheduled for May 2020, at which point the SHIP system will be the largest in Europe. The currently biggest one has 9,300 m² (6.5 MWth) and supplies heat to a flower farm in the Netherlands.