(Photo credit: Sinovoltaics)

(Photo credit: Sinovoltaics)Sinovoltaics, a Dutch-German provider of quality assurance for the Solar photovoltaic (PV) and Battery Energy Storage System (BESS) industries, is expanding into the United States and establishing offices.

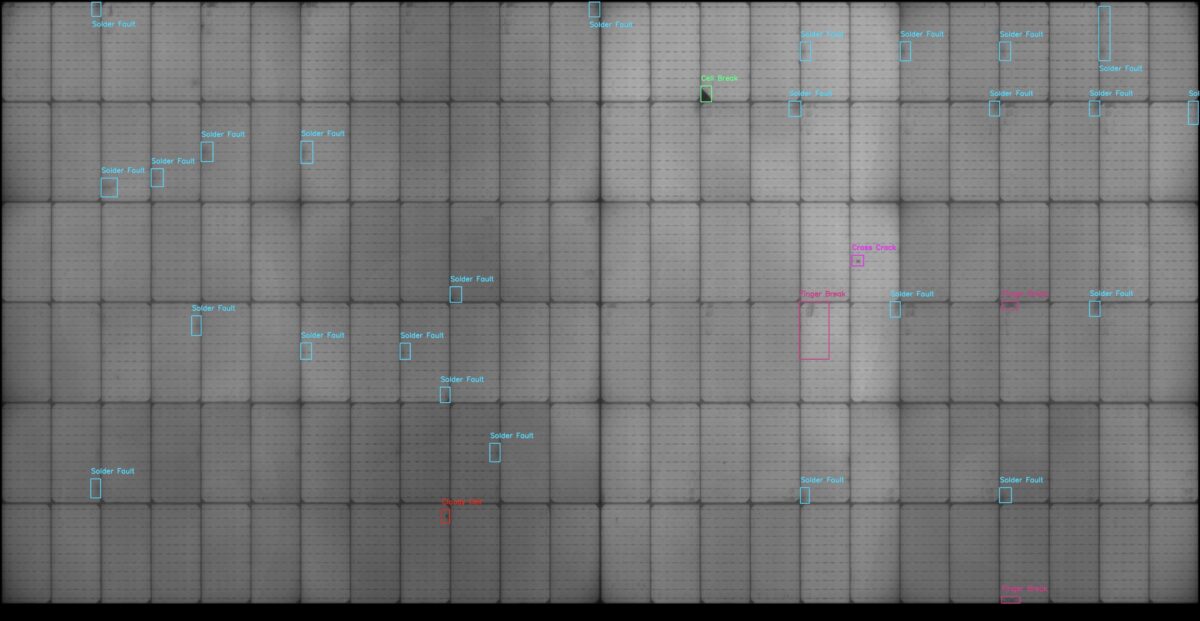

Fueled by the Inflation Reduction Act’s (IRA) solar and energy storage manufacturing boom, the company aims to target the solar module quality assurance market with its “Zero Risk Solar” quality inspection service that uses AI-driven Electroluminescence (EL) analysis to review every module and prevent orders from shipping with microcracks and other defects.

Sinovoltaics’ services include quality assurance inspections, factory audits, ESG, and traceability audits for utility solar developers and investors. It has audited more than 200 solar photovoltaic module factories, more than 35 energy storage and inverter manufacturing facilities, and inspected more than 18 GW of solar and storage products at factories across 15+ countries for clients from over 45 countries across 6 continents, the company said. Sinovoltaics’ credentials include certification to ISO 17020, ISO 9001, as well as a CQI/IRCA-accredited and SA8000-certified team of auditors.

Sinovoltaics is expanding into the U.S. when Asian solar module prices are decreasing. At the same time, solar PV and BESS manufacturers are building new factories to capture IRA incentives and stay competitive. Sinovoltaics says these market conditions are compelling global manufacturers to become more efficient and reduce costs, raising investor concerns about maintaining quality standards.

Sinovoltaics developed SELMA (Sinovoltaics EL Mass Analysis), which the company says differs from traditional electroluminescence (EL) quality assurance techniques that test a portion of modules using sampling. Instead, Sinovoltaics says SELMA inspects 100% of purchased modules for microcracks and other cell-inherent defects.

Recent PVEL analysis determined that glass//glass modules, which are steadily gaining market share with the popularity of bifacial modules, are more than twice as likely to break compared to glass//backsheet modules.

Since 2020, Sinovoltaics says SELMA has been implemented at “all the major Tier 1” solar manufacturers. In 2023, more than 4 million PV modules were inspected, the company said. Replacement rates of 1-3% were common at Tier 1 factories, reflecting hundreds of thousands of defective PV modules prevented from being shipped.

“100% module inspections is the only way to ensure high-performance solar projects,” said Dricus de Rooij, co-founder and CEO of Sinovoltaics. “Our goal is to help solar manufacturers to deliver—and for solar developers to receive—the highest quality solar modules. That’s why Sinovoltaics inspects 100% of PV modules and does not rely on sampling methods. Every module is inspected by SELMA and replaced, if necessary, before their clients’ orders leave the factory.

Under Sinovoltaics’ Zero Risk Solar service backed by Munich Re, PV modules procured by Sinovoltaics’ clients are guaranteed to be defect-free before shipping. If any warranty claim is filed within three years, Sinovoltaics will pay liquidated damages to cover costs, such as de-assembly, manpower, and logistics.

“It doesn’t matter if the panel is made in the U.S. or at a facility in Asia, de Rooij added. “Our objective is that our clients operate high-performing projects for more than 40 years. In the event that a warranty claim occurs on-site, we have skin in the game to compensate our clients through our insurance partner, Munich Re.”