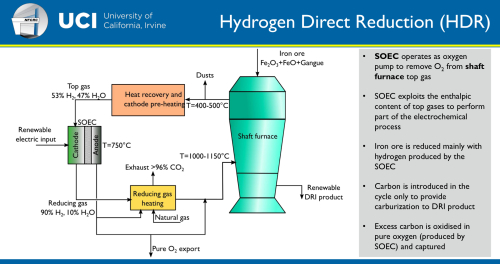

Led by the University of Wisconsin-Madison, this project will demonstrate a first-of-a-kind integration of a solid oxide electrolyzer cell (SOEC) with an industrial direct reduction shaft furnace, offering an opportunity to reintegrate waste heat into hydrogen generation. This hydrogen can be reutilized to produce direct reduced iron.

This project builds on the HySteel project led by UC Irvine’s Advanced Power and Energy Program.

Source: UC Irvine

Additionally, an SOEC does not require scarce platinum group metal catalysts for hydrogen production. The goal is to demonstrate at least 90% GHG emissions reduction potential for direct reduction ironmaking at a production capacity of 1.6 million tons per year.

This project directly supports hydrogen applications for industrial decarbonization, a key technology area identified in the national clean hydrogen strategy that further aligns with the priorities of the Hydrogen Interagency Task Force, which is coordinating a whole-of-government approach to advancing clean hydrogen.

These efforts include tax incentives in the Inflation Reduction Act and ongoing research, development, and demonstration to drive down the cost of clean hydrogen and achieve the Hydrogen Shot goal of $1 per kilogram within a decade.