The steel containment shell is an important part of the nuclear island reactor building and the third safety barrier to prevent the leakage of radioactive materials, the company noted.

The steel containment vessel of the CAP1000 - the Chinese version of the Westinghouse AP1000 - is composed of five modules: the bottom head, first cylinder ring, second cylinder ring, third cylinder ring, and top seal.

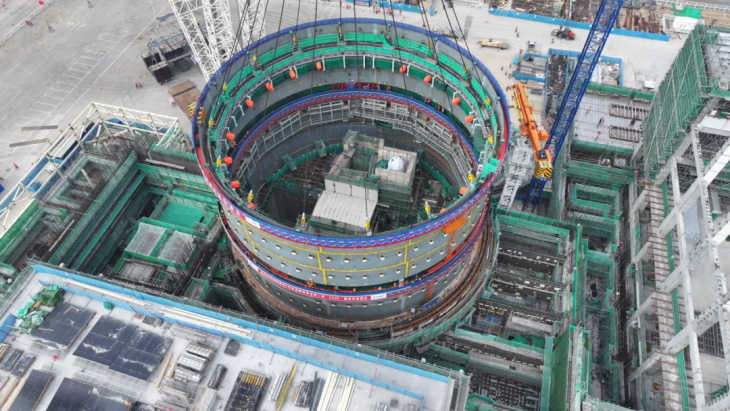

The third cylinder ring - with an inner diameter of almost 40 metres, a height of 11.6 metres and the total weight of about 660 tonnes - was hoisted into place on 16 March in an operation lasting just under two hours.

The component is hoisted into place (Image: SNERDI)

"After the hoisting is in place, personnel can directly access the ring crane, which improves construction efficiency, reduces safety risks, and lays a solid foundation for the milestone nodes of the ring crane to be used, and provides a solid foundation for the nuclear power plant," SNERDI said.

The construction of two CAP1000 reactors at each of the Haiyang, Sanmen and Lufeng nuclear power plant sites in China was approved by the country's State Council on 20 April 2022. The approvals were for Haiyang 3 and 4, Sanmen units 3 and 4 and units 5 and 6 of the Lufeng plant. The Sanmen and Haiyang plants are already home to two Westinghouse AP1000 units each.

Unit 1 of the Haiyang plant entered commercial operation in October 2018, with unit 2 following in January 2019. Together, Haiyang units 1 and 2 can provide some 20 TWh of electricity to the grid annually, sufficient to meet one-third of household demand in Shandong province.

The first safety-related concrete was poured for the nuclear island of Haiyang unit 3 in July 2022. Construction of Haiyang 4 began in April last year. The SNERDI said the planned construction period for Haiyang 3 and 4 was 56 months, with the two units scheduled to be fully operational in 2027.