When it comes to making the switch from using fossil fuels to cleaner renewable energy, one of the difficulties encountered is the storage and distribution of excess energy. Thus, the question that looms large for many is how to improve energy storage and energy distribution in order to move towards a sustainable future. Now, a team of researchers claims that nanomaterials can provide the necessary boost to overcome this hurdle.

Published in the journal Science, the team of scientists at Drexel University believes that accelerating the integration of nanomaterials into power storage systems is the key to cost-effective energy storage solutions on a mass scale.

The research reveals that by incorporating nanomaterials into batteries the current technology that uses metals such as copper or aluminum as foil collectors can be thrown out. The result will be lighter, more compact batteries that can charge and discharge energy at a faster rate.

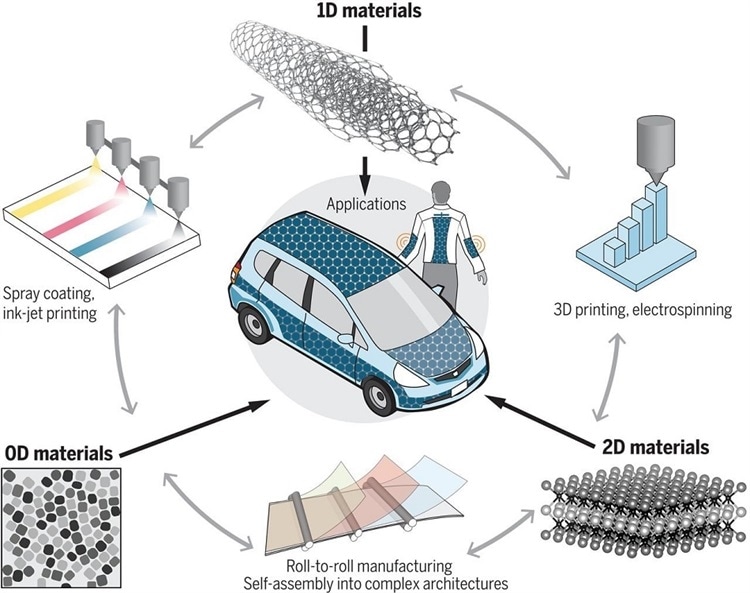

Nanomaterials offer scientists a new opportunity to imagine new possibilities for the future of energy storage in batteries. By implementing a process known as nanostructuring, researchers can introduce stacks of nanoscale materials into the design process of conventional batteries and supercapacitors. What’s more is that nanomaterials can enhance the flow of electrons because of their atomic structure and shape: the greater surface area creates an efficient system for storing the charged particles.

However, while this is an exciting time to be researching the field of nanomaterials and energy storage new strategies are key when attempting to realize the build of nanoparticles into architectures with controlled geometries. “We now have more nanoparticles available than ever — and with different compositions, shapes and well-known properties. These nanoparticles are just like Lego blocks, and they need to be put together in a smart way to produce an innovative structure with performance superior of any current energy storage device,” said Ekaterina Pomerantseva, an associate professor at Drexel College in the department of Engineering and co-author of the study.

However, unlike Lego, the structuring of nanomaterials is particularly challenging as it can be difficult to determine which nanoparticles can be connected in order to produce stable architectures.

Another challenge faced is the upscaling and the development of the new technology for commercial production. This is because to adapt and implement the application of nanomaterials into conventional manufacturing for battery cells could mean an expensive overhaul of techniques that have been in use for over 50 years.

Yet, while the common belief is that nanomaterials are too costly for mass production. Gogotsi stated, “This has already been accomplished for carbon nanotubes with hundreds of tons manufacturing for needs of battery industry in China. Preprocessing the nanomaterials in this way would allow the use of current battery manufacturing equipment.”

Furthermore, Gogotsi and his team also highlight the fact that using nanomaterials and putting their technology into commercial production would eradicate some of the toxic waste materials found in conventional batteries. “Whenever scientists consider new materials for energy storage, they should always take into account toxicity to humans and environment, also in case of accidental fire, incineration or dumping into waste,” said Gogotsi.

Other enterprises also exploring energy storage solutions include Tesla’s Megapack and ABB’s PowerStoreTM, as attempts are made to find more sustainable energy solutions that aid rather than destroy the planet. Moving away from the use of materials traditionally used in batteries, as well as the burning of fossil fuels would address just some of the many environmental concerns we have today.