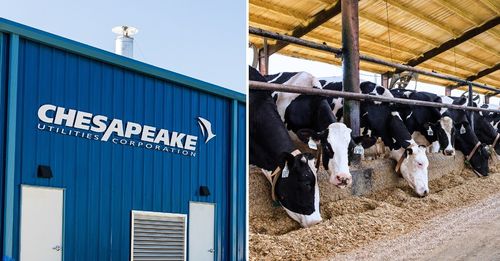

The injections are part of the commissioning phase of the Company’s first RNG development project, which included the construction and operation of a dairy manure-to-biogas RNG facility at Full Circle Dairy. The facility is now producing RNG, with the first deliveries and injections of captured RNG taking place earlier this month. The RNG is transported from the facility to the injection site by Chesapeake Utilities’ subsidiary Marlin Gas Services, a provider of virtual pipeline solutions. To date, during the facility’s first month of production, approximately 4,700 dekatherms of RNG have been captured and transported to the injection site.

“This RNG project builds upon Chesapeake Utilities’ solid foundation, legacy assets and focus on operational excellence,” said Justin Stankiewicz, general manager. “It highlights our ability to play a pivotal role in the entire RNG value chain, from production to transportation, injection, and finally, transmission and distribution of the pipeline quality gas.”

The RNG facility at Full Circle Dairy, which began construction in February 2023, captures and cleans methane from manure generated by dairy cows. The facility is expected to produce an average of 100,000 dekatherms annually and represents a capital investment of $22 million. The facility is projected to capture and redirect approximately 1,116 metric tons (mt) of methane per year, equivalent to 27,900 mt of carbon dioxide. Using the EPA greenhouse gas equivalencies calculator, this methane reduction equates to over 6,000 gasoline-powered passenger vehicles driven for one year and a CO2 emissions reduction equivalent to the annual energy consumption of more than 3,500 homes.