According to XINTC, this breakthrough could significantly reduce the cost of hydrogen production, unlocking new opportunities to scale up hydrogen adoption on a global scale.

Advancing efficiency with cutting-edge technology

Thanks to intelligent electronics, XINTC’s gas modules can switch on and off at high frequency – up to hundreds of thousands of cycles – without experiencing significant wear and tear. This allows the system to extract up to 25% more hydrogen from a single solar field compared to other manufacturers’ solutions.

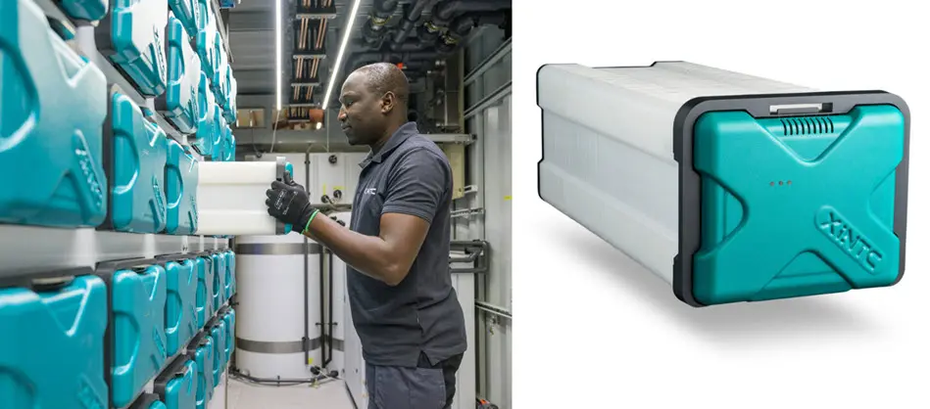

The XINTC electrolyser system is built from four modular building blocks, designed to meet varying requirements for production capacity, storage volume, hydrogen purity, and output pressure. All modules are standardised and can be made operational within a single day of installation.

Versatile applications and global reach

XINTC’s target market includes mid-range systems ranging from 500 kW to over 100 MW, making the technology suitable for a wide array of applications such as ammonia production, steel furnaces, fertiliser manufacturing, industrial heating, biomethanisation, and mobility solutions.

Production of gas modules and system assembly will take place on multiple continents, supported by a global network of distributors. The company has already received significant interest from international stakeholders eager to adopt this innovative electrolyser technology.

Official launch and demonstration facility

On 9 December 2024, the H2 Experience Centre in Kootwijkerbroek, the Netherlands, will officially open, marking the global launch of XINTC’s pioneering electrolyser design. Established in collaboration with Energeion, the facility serves as a testing and demonstration hub, showcasing the electrolyser’s ability to be directly coupled with solar fields and to adapt in real time to fluctuations in renewable energy sources.