Scientists at the Artvin Çoruh University in Turkey have developed a new solar module cooling technique that utilizes electrospray cooling for the first time at the research level.

This technology is used for heat removal in electronic components and reportedly has a powerful cooling capacity, a small liquid supply, and precise temperature control. Another important advantage is that the spray particles are smaller than mechanical atomizers, with droplet production being more homogeneous. Furthermore, it is claimed to be easier to use and to have lower energy consumption compared to conventional spray cooling.

“Electrospray cooling is a new topic in the literature, especially used for cooling electromechanical systems of processors,” the research's lead author, Abdüssamed Kabakuş, told pv magazine. “Before this study, it has never been investigated for cooling PV systems. When the literature is examined, the most important feature of electrospray cooling is that it can perform high heat transfer at low coolant fluid flow rates and consumes less energy than mechanical spray systems.”

The research group carried out a series of experiments on a small panel. “As a result of the experiments carried out on this panel, a very effective cooling performance was obtained,” Kabakuş added. “However, this method has some disadvantages. Since the projection area of the spray sprayed from a single spray nozzle is small, it will not be possible to use it with a single spray on industrial panels.”

Electrospray cooling combines spray cooling and high-voltage electrostatic technology. It produces an electric voltage between a high-temperature metal or metal-coated surface and a stainless steel nozzle. The nozzle provides a liquid with low surface tension and the liquid particles hitting the hot surface cause cooling by removing heat through the high heat transfer on the surface.

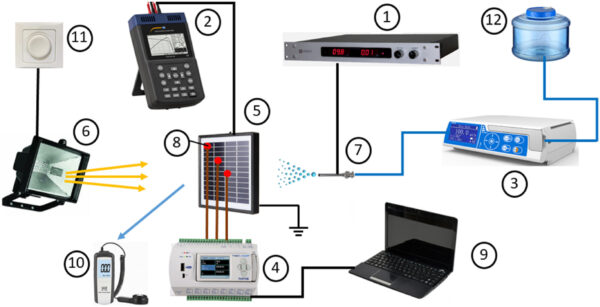

The system used in the experiments uses water as the coolant agent. An infusion pump was utilized to deliver refrigerant to the stainless steel nozzle at a constant flow rate. The rear side of the solar panel was covered with a 0.016 mm aluminum foil pasted with a heat conduction paste. The PCE-PVA 100 solar module analyzer was used to assess module performance. T-type thermocouples were used to measure its operating temperature.

“The experiments were carried out for 800, 1000, and 1200 W/m2 radiation intensity, 20 kV electrical voltage, and 40-60-80-100-120 ml/h coolant fluid flow rates,” the researchers explained. “They were carried out in a laboratory environment, where the cooling water temperature is approximately constant and steady-state with the ambient temperature.”

The analysis showed that the panel temperature decreased as the flow rate increased, for all irradiance levels. “At flow rates above 80 ml/h, there was no significant change in temperature alternation. 80 ml/h of flow rate was determined as the optimum flow rate,” the group emphasized. “At a flow rate of 80 ml/h, the rate of the temperature decrease was determined as 0.13, 0.14, and 0.15 C/s for 800-1000-1200 W/m2 of irradiances, respectively.”

The measurements also showed that the solar module output increased by between 24.2% and 56.5%,

The cooling technique was presented in the study “A new approach to cooling photovoltaic panels: Electrospray cooling,” published in Case Studies in Thermal Engineering. “In future studies, an electrospray system with multiple nozzles will be established for cooling industrial panels and the cooling performance will be examined,” Kabakuş said. “Only after its usability for industrial panels is proven, a calculation will be made regarding the system cost.”