The ENBIO project uses excess energy from wind turbines to power 16 1,000-litre photo-bioreactors which grow algae that can then be used for biofuels. The project demonstrates how green technologies can work together, but can it make algae-derived fuel competitive? We find out more.

The science

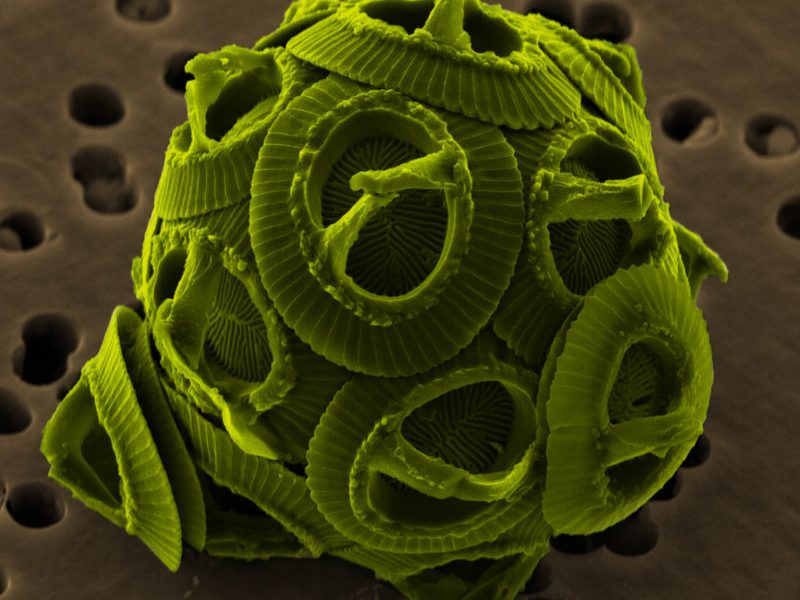

The Scotland-based BioEconomy (ENBIO) project builds on findings from the Algal Solutions for Local Energy Economy (ASLEE) project, which developed the Pandora internally-lit photobioreactor in its efforts to investigate the potential of novel algal products at scale.

This bioreactor uses LED technology to produce microalgae, with scalable and modular cultivation systems to allow integration with local renewable energy grids.

The project’s base in Scotland makes use of the renewable energy generation potential in the Highlands and Islands of Scotland, which according to ENBIO is some of the best in Europe, without adding to the grid constraints that can hinder economic development in these areas.

ENBIO integrates renewable electricity generation with large scale microalgal production, making use of excess renewable energy from local infrastructures to power the production of algal products and feedstocks by the Pandora photobioreactors.

This combination adds value to existing renewable energy generation and significantly reduces electricity costs for bioproduction by using renewable energy at times of excess.

ENBIO business development officer Carole Shellcock says that although this technology is primarily used for the agriculture industry, there is potential for its use in biofuels: “Since microalgae are grown using only light, CO2 and nutrients, the use of algae-based fuel could limit the impact on the environment.”

The reality of algae derived fuel so far

Algae-derived fuel was an exciting prospect for energy companies in the early 2010s, with a number of investments made into exploring the potential of algae fuels to combat the climate crisis and facilitate the development of renewable energy sources.

In 2010 the Algae Biomass Organisation (ABO) predicted that algae fuel would reach price parity with oil by 2018, with ABO head at the time Mary Rosenthal expecting “several billions of gallons” of algae to be produced as a fuel source by 2017.

The world’s first building powered entirely by algae was unveiled in Hamburg in March 2013, using 129 bioreactors to generate power and heat for a four-story residential building.

This optimistic approach to algal fuels also encouraged investment at scale from energy companies, with US-based Sapphire Energy and Spanish Aqualia starting development of algae-based biofuel facilities in August 2013.

However, the reality of algae-based fuel today is far from the green superfuel predicted by the energy industry, and although these algae projects demonstrate the utility of existing renewable energy infrastructures, the viability of algae as a fuel source itself is up for question.

Shellcock says: “If we are talking about algae-based fuel, production cost is the main limitation. For the moment it’s around £10 per litre of biodiesel. The quantity of algae that needs to be produced to enter the market is huge compared to the current global production.

High-maintenance and high input costs

A major problem with algae as a fuel source is the high-maintenance growing conditions required to produce the required quantities of algae – the plants need large open ponds, and significant volumes of CO₂ and fertiliser to enable the algae to photosynthesise fast enough at large scales.

Swansea University marine biologist Professor Kevin Flynn wrote in 2017: “The dream has been broken not by failings in engineering, but by the inefficiency of biochemistry. Simulations of microalgal biofuel production show that to approach the 10% of EU transport fuels expected to be supplied by biofuels, ponds three times the area of Belgium would be needed.

“And for the algae in these ponds to produce biofuel, it would require fertiliser equivalent to 50% of the current total annual EU crop plant needs.

“Ironically, such ponds would also need to be located near heavy industry which produces CO₂ to provide the level required by the microalgae for photosynthesis.”

Another issue with algal fuels is energy- with current methods, it takes more energy to produce algal fuels than it would provide as power. This, coupled with the costs needed to produce algae at scale, means that algal technologies in their current state are neither effective nor efficient enough to supplant oil as a renewable energy source.

In response to this disappointment, many companies that started on the idea of algae as an alternative to oil have shifted their business models to algal production of products such as feed and cosmetics. The ENBIO and ASLEE projects have similar goals, integrating renewable energy infrastructures into the manufacturing of bioproducts rather than relying on algae as a fuel source.

Explaining the current state of algal technology, Shellcock says: “At the moment algae-based fuel is not able to replace oil based fuels due to the economics of production.

“It has potential to be used as a supplement in classical fuel. Algae-based products have potential to be integrated into the biobased feedstocks, perhaps as part of a biorefinery approach.”

The future of algae-based fuels

While the energy industry as a whole has fallen out of love with algae-based fuels, and the technology is unlikely to become competitive or economically viable any time soon, projects like ENBIO and ASLEE show it should still be part of the conversation, especially as other small breakthroughs are still being made to refine biofuels.

In March 2019, a team of chemical engineers from the University of Utah developed a new biocrude production method to more efficiently extract the important lipids from algae.

This method involves shooting jets of solvent at jets of algae, creating enough turbulence to transfer lipids from the algae to the solvent stream. This removes the energy-intensive drying process needed with current algal fuel production, vastly increasing the efficiency of the biofuels produced.

In a press release, co-author of the study Dr Leonard Pease said: “The key piece here is trying to get energy parity. We’re not there yet, but this is a really important step toward accomplishing it.

“We have removed a significant development barrier to make algal biofuel production more efficient and smarter. Our method puts us much closer to creating biofuels energy parity than we were before.”

Researchers at the US National Renewable Energy Laboratory’s (NREL) National Bioenergy Centre have also attempted to improve the efficiency of algae-based biofuels, with strategic project lead Philip Pienkos explaining these efforts in a June 2018 article for R&D World.

Pienkos suggests an alternative solution to the current biofuel production process, converting the biomass left over from the drying process into biogas that would then go into the production of biofuel to ensure that no component of the algal biomass goes to waste.

The NREL also proposed a Combined Algal Processing scheme, which would use the by-products of biofuel production to produce a number of other important chemicals such as plastic composites, polyurethanes and surfactants.