Researchers at the University of Exeter in the United Kingdom have simulated a 1 GW agrivoltaic farm power hydrogen generation in Australia, California, China, Nigeria, and Spain and have found that tomatoes could be the most suitable crop to be grown under the solar panels.

“Producing hydrogen with agrivoltaics would be technically and economically feasible also under the 1 GW threshold,” the research's lead author, Aritra Gosh, told pv magazine. “This scale was not employed due to an economy-of-scale requirement, although the proposed combination may benefit from this. We selected this capacity to provide a clear and comprehensible benchmark for industry and governmental stakeholders, facilitating comparisons with other large-scale renewable energy projects. Smaller scales or grid-connected projects could also be feasible.”

The proposed project configuration includes a 1 GW off-grid agrivoltaic facility, 300 proton exchange membrane (PEM) electrolyzers, converter systems, compressors, and storage systems to fuel hydrogen fuel electric cell vehicles (FCEVs). The hydrogen refuelling system consists of high-pressure storage tanks, a hydrogen refuelling station, and car refuelling demand.

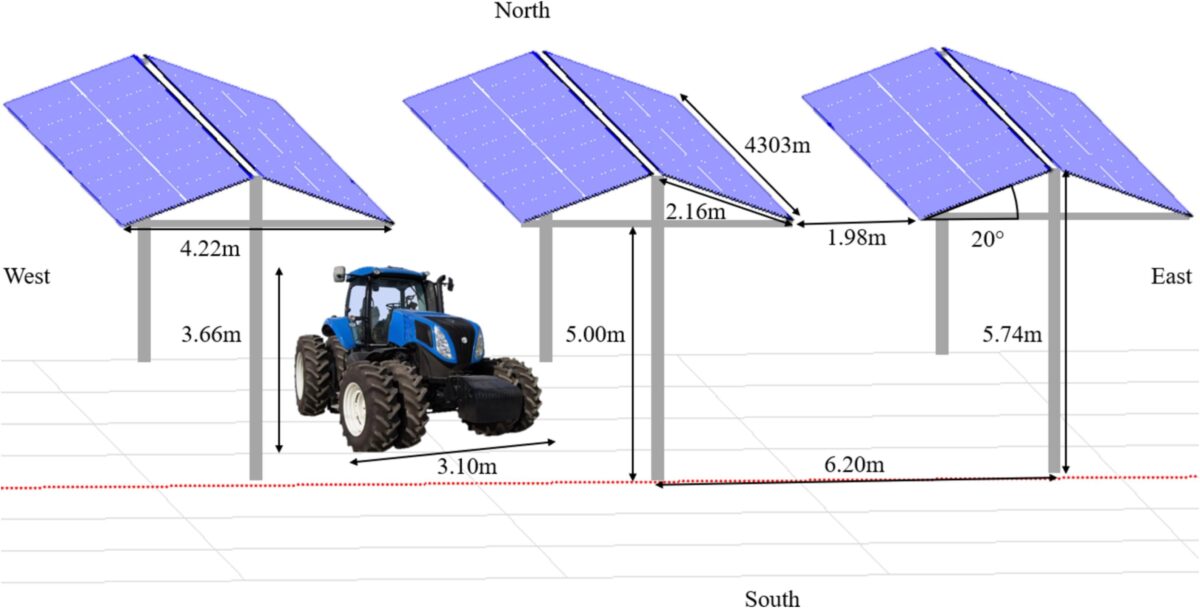

The agrivoltaic array was assumed to use 2,272,752 bifacial monocrystalline solar modules with each an output of 440W and 200 inverters with each a nominal capacity of 500 kW. The panels were assumed to be deployed with a tilt angle of 20 degrees and to occupy an area of 5,095,083 m2. “In addition to the agrivoltaic PV system, a ground-mount solar PV system has been designed and simulated in PVsyst to facilitate the calculation of each site location's land equivalent ratio (LER),” the scientists stated. LER is a method used to measure land use efficiency for the simultaneous production of crops and electricity.

Their techno-economic analysis considered 125 site configurations and took into account net present value (NPV), internal rate of return (IRR), total profit, simple payback time, capex, opex, and levelized cost of hydrogen (LCOH). It reportedly showed that the proposed combination could provide a levelized cost of hydrogen ranging from GBP 3.06 ($3.90)/kg in Nigeria to GBP 6.38 ($8.13)/kg in Spain. It also demonstrated that the Nigerian site had the highest number of HPV refuelling at 3.75 million per year, while the Spanish site location was found to have the lowest amount at 3.11 million per year.

The analysis also showed that tomatoes would be the best crop to be grown under the panels, with agricultural yield losses being estimated at between 9.40% and 36.94%. “Our analysis looked at growing tomatoes as it was suitable in each of the analysed locations' soil types,” said Gosh. “Tomato plants are not the most shade-tolerant crop that can be grown in an agrivoltaic system and, therefore, highly shade-tolerant crops may result in less reduced crop yields or even increased crop yields in certain climatic conditions, with the PV array providing microclimate benefits, such as shade against too much irradiance and heat, and increased humidity.”

According to Gosh, the research's findings show that combining off-grid agrivoltaics with hydrogen generation is a viable model for enhancing land utilization while generating additional income. “The benefits of land recovery and additional income from electricity generation should offset the reduced harvest yields,” he emphasized. “Key findings indicate that all locations demonstrate suitability for agrivoltaic applications.”