A team from King Abdullah University of Science and Technology (KAUST), Beijing Institute of Nanoenergy and Nanosystems, and Georgia Tech has developed a a wave-energy-driven electrochemical CO2 reduction system that converts ocean wave energy to chemical energy in the form of formic acid, a liquid fuel.

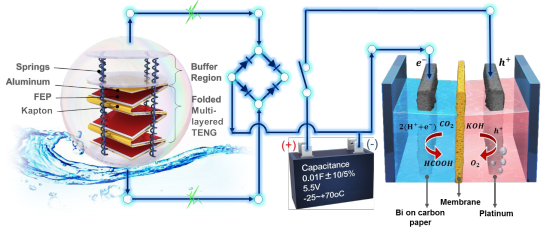

The system, described in an open-access paper in the RSC journal Energy & Environmental Science, mainly consists of a spherical spring-assisted triboelectric nanogenerator (TENG) to convert the mechanical energy of the wave to electrical energy; a power management circuit with a supercapacitor to temporarily store the harvested electrical energy; and a electrochemical setup to reduce carbon dioxide to formic acid.

This type of TENG is more cost-effective compared to conventional EMG-based wave energy converters. Moreover, it features a higher wave energy conversion efficiency and power output as compared to previous TENG designs and is able to float on the water’s surface, which minimizes both the environmental impact and simplifies operation and these features are essential for the practical use of TENGs on ocean wave energy harvesting application.

—Leung et al.

The team optimized the charging process of the supercapacitor and the operation potential of the electrochemical cells to more effectively utilize the energy harvested from the nanogenerator and maximize the production of formic acid.

Under simulated waves, the system can produce 2.798 µmol of formic acid per day via the wave energy harvested from a water’s surface area of 0.04 m2.

They also performed field tests in the Red Sea to demonstrate the practicality of such an electrochemical CO2 reduction system. According to the field test results, the wave-energy-driven CO2RR system can produce 0.325 μmol of formic acid per day at 18 knots wind speed.

Finally, they present design guidelines for achieving a cost-effective, efficient, and large-scale wave-energy-driven CO2 reduction system for liquid fuel production.

From our estimates based on the experimental results, we believe that a wave-energy-driven CO2RR system installed with 1 km2 of TENGs can generate about 56% of the daily per capita energy consumption in the world … Nonetheless, there is still room for improvement in the energy conversion efficiency of the system.

While the major components, including the TENGs, power management circuit, electrochemical cell, and catalysts, are all fairly mature, substantial optimization is still needed when combining them for an efficient wave-energy-driven CO2RR system.

First, the energy storage efficiency should be improved by better matching the impedance between the TENGs and the energy storage components. Despite extensive research on improving the charging efficiency of the capacitor by the TENGs, further studies are still needed since the load capacitance of the capacitor and inherent capacitance of the TENG will depend on the targeted energy production and TENG design. In addition, Zi et al. have reported the designed charging cycle can significantly improve the energy-storage efficiency up to 50%. The higher energy-storage efficiency is essential for practical use of TENGs to harvest ambient mechanical energies. Second, in order to deliver a higher power output and more effectively utilize the ocean wave energy, the design of the TENG must be further improved to better accommodate the actual dynamics of ocean waves rather than a lab-simulated wave.

… We foresee that substantial works must be done in the future to achieve practical use of such a wave energy harvesting system. For example, when advancing the design and scaling up the power output of TENGs, the inherent impedance will vary which can significantly alter the optimal charging condition to the energy storage device. Besides, scaling up the effective area of TENG will unavoidably largely increase the size and the physical distance between the TENGs and power management unit, which will introduce problems such as loss of energy in the connection between the components and these problems need substantial efforts to overcome. Finally, besides the above, the cost of fabricating the TENGs must be lowered, and it should be made more convenient to form a large network of TENGs to deliver cheaper and higher wave power output.

—Leung et al.