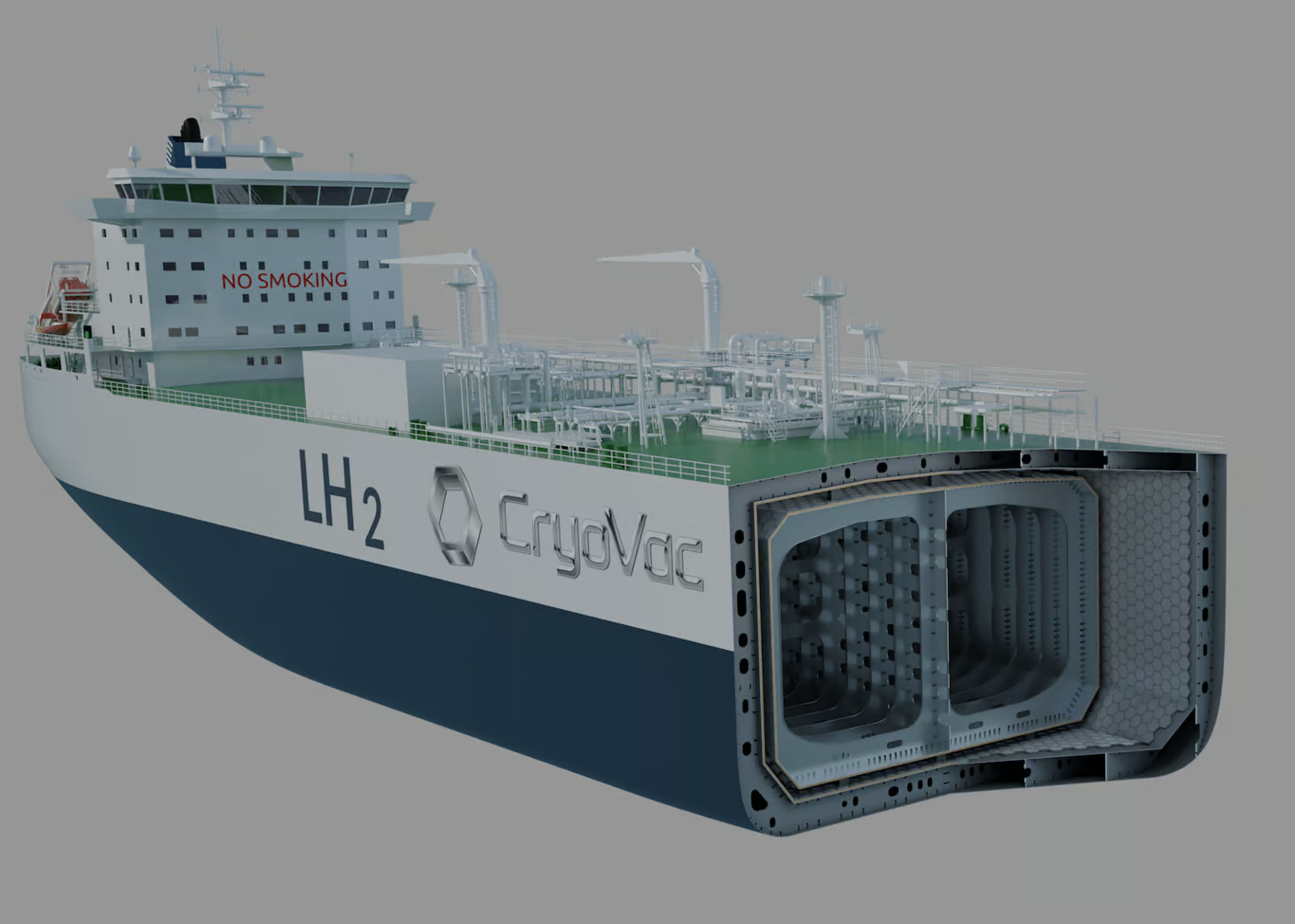

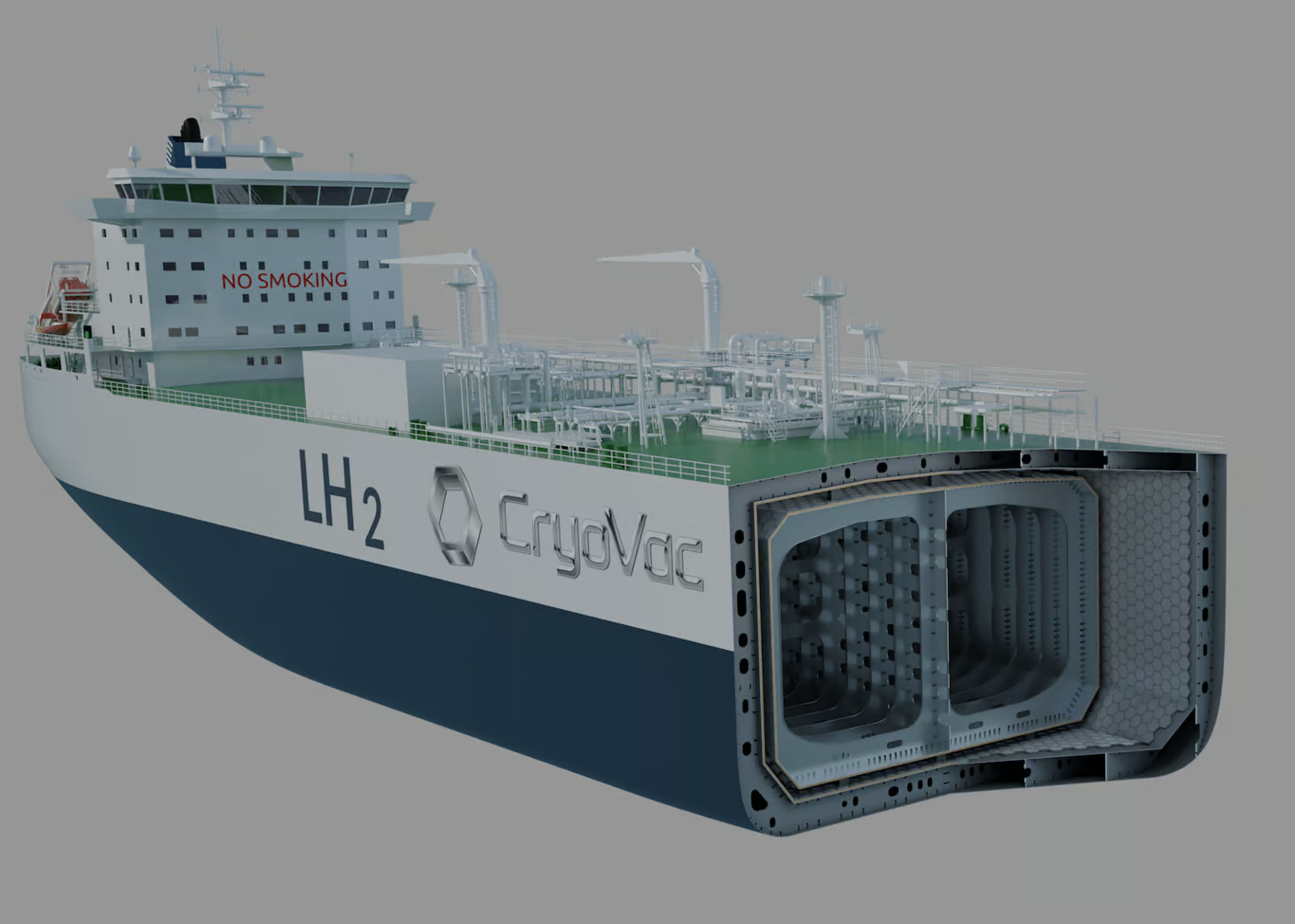

The cryogenic hydrogen storage-based solution involves cooling hydrogen to around -253°C. The Norwegian firm has developed the “world’s first” liquid hydrogen containment system that uses prismatic tanks for ship transport, which utilises a hexagonal vacuum insulation panel.

“Our hexagonal vacuum panels are welded together into continuous surfaces and configured to form a hybrid insulation system allowing simple prismatic tanks to be applied for liquid hydrogen carriage,” explained Aage Bjørn Andersen, CEO of CryoVac.

“This provides insulation with a very low boil-off rate, without challenging the integrity of the steel,” the CEO added.

The confirmation of the AiP confirms that the design is “feasible and that no significant obstacles exist to prevent it from being realised,” according to CryoVac’s statement.

The next step for CryoVac is to develop a 45,000m3, long-haul liquid hydrogen carrier comprising three cargo holds each holding a 15,000m3 tank.

The Vikersund-based company intends to collaborate with DNV to obtain the General Approval for Ship Application (GASA).

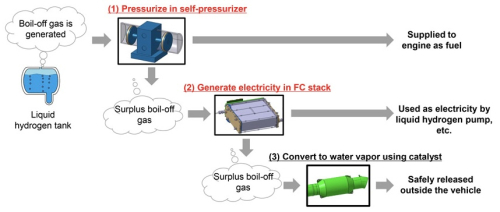

The vessel is expected to both transport liquid hydrogen and run on hydrogen. “There is a lot of interest worldwide for a safe and cost-efficient solution for shipping of liquid hydrogen,” Andersen claimed.

“This is the technology gap we are aiming to fill. Going forward, we will be entering into dialogue with shipowners and hydrogen producers that share the ambition of realising a global supply chain for liquid hydrogen.”