NeoSmelt is tipped to take significant steps toward decarbonising iron and steelmaking at scale.

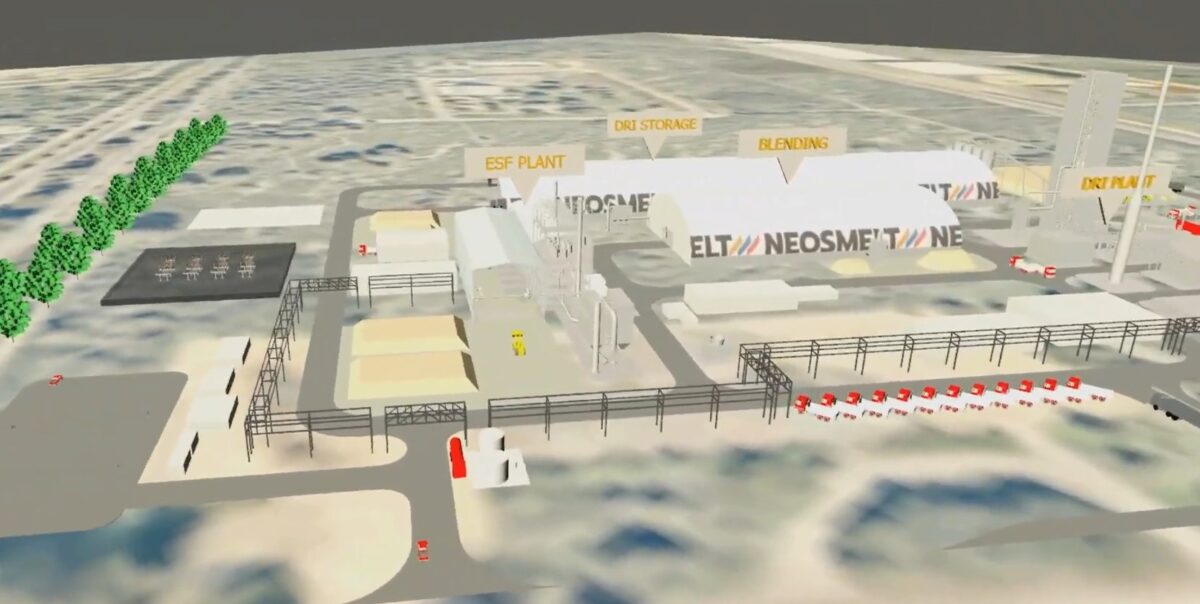

Australia’s largest ironmaking electric smelting furnace (ESF) pilot plant, Project NeoSmelt, is set to be built in the Kwinana Industrial Area south of Perth, Western Australia (WA) which is also home to the dual-stage Kwinana battery storage system and Kwinana power station.

NeoSmelt is to be designed and built by a consortium, which includes steelmaker BlueScope as project manager, and iron ore producers BHP and Rio Tinto, plus Woodside Energy, will join as an energy supplier, and expected to produce 30,000 to 40,000 tonnes of molten iron a year.

Woodside is currently developing a hydrogen production facility in Kwinana, called H2Perth, which will produce both blue and green hydrogen.

The early phase of H2Perth will produce blue hydrogen from methane gas using carbon capture (CCS) to mitigate emissions, and then transition to green hydrogen production through electrolysis using as yet undisclosed renewable electricity sources.

NeoSmelt will produce iron without metallurgical coal using testing the direct reduced iron (DRI)-ESF technology.

BlueScope Chief Executive Australia Tania Archibald said the pilot build is substantial, and the hope is to skip the project quickly to full commercial scale to help the decarbonisation of steel making.

“This goes to the heart of the challenge for Australia’s biggest export industry, which is how to use the Pilbara ores, which tends to be lower grade, medium grade ores, in a DRI process, which is one of the most prospective pathways to low-emissions iron and steel making,” Archibald said.

“BlueScope’s role as project manager leverages our deep iron and steelmaking experience at the Port Kembla Steelworks and our unique capability as the operator of the world’s only electric smelting furnace processing DRI in New Zealand.”

Together, the DRI-ESF equipment can replace the traditional blast furnace with estimates showing reductions of up to 80% in CO2 emission intensity potentially achievable.

Subject to funding, the project anticipates a decision to enter feasibility studies in Q2 2025 and is targeting final investment decision (FID) for the pilot plant in 2026, with operations expected to begin in 2028.

Government of WA Premier Roger Cook said securing NeoSmelt for Kwinana positions WA at the cutting edge of the global push to slash emissions from steel.

“Putting the global steel industry on the pathway to zero emissions means more jobs in processing in WA, and a strong future for WA’s iron ore industry,” Cook said.

Rio Tinto Iron Ore Chief Executive Simon Trott said better ways to produce the most commonly used metal in the world need to be found, while meeting the needs of the planet and climate objectives.

“The NeoSmelt pilot plant builds on the suite of projects Rio Tinto has underway with our customers and suppliers to find better ways to accelerate their efforts to meet their decarbonisation targets,” Trott said.

Woodside Energy Executive Vice President and Chief Operating Officer Australia Liz Westcott said gas and hydrogen may enable emissions reductions in steelmaking and the company supports the NeoSmelt project’s goals of exploring lower-emissions steelmaking pathways for Pilbara iron ores.