“Highly UV-transparent encapsulants allow to exploit the entire wavelength range of sunlight. Their use in the fabrication of a photovoltaic module is therefore particularly useful to increase energy conversion efficiency. However, the formulation of an encapsulant that is UV-transparent and at the same time chemically resistant to degradation is particularly challenging and demanding,” Valeria Fiandra, corresponding author.

The team performed an initial chemical structure analysis of the PV encapsulants. It noted that Fourier transform infrared spectroscopy (FTIR) analysis revealed that the POE, labeled POE-8110, was an elastomeric copolymer of ethylene and propylene and the TPO was a side-chain crystalline polymer: poly(ethylene-co-octadecyl acrylate).

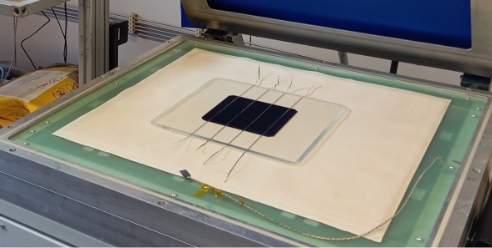

To verify behavior in a realistic module configuration, the team fabricated crystalline silicon (c-Si) devices measuring 30 cm × 30 cm. The composition of the mini-modules was as follows: glass on the front, half-cut c-Si cells, PET film on the back side, plus one of three encapsulants under investigation, which were applied according to the manufacturer’s instructions.

The UV aging tests pushed up to 6000 h of irradiation and 1800 kWh/m2 UV dose to reveal the degradation effects on the various materials, according to the paper. The team looked at how the UV affects the loss of electrical performance, and to what degree. The results were compared to the performance of standard EVA, labeled EVA-05HTL.

The characterization was done using X-ray diffraction, and Raman spectra were recorded. The samples were measured in transmittance mode. Yellowness index (XI) measurements were also carried out with each sample measured in triplicate. The carbonyl index (CI) was monitored, and a scanning electron microscopy (SEM) analysis was completed.

“During aging, all encapsulants undergo chemical degradation, evidenced by yellowing, polymer bond breaking, and the formation of oxidation products containing carbonyl groups,” noted the team, adding that TPO is the “most chemically stable polymer,” as demonstrated by FTIR and Raman analysis and by the negligible change in its yellowness index (YI) value.

The team found that the most significant degradation was detected for the mini-device made with EVA-05HTL. “This result is due to the presence of the acetate group in the EVA molecule, absent in POE and TPO, which leads to the production of acetic acid and determines both the corrosion of the metals and the propagation of degradation,” it said.

Furthermore, the POE and TPO maintained their performance better than EVA, “not only because they do not produce acetic acid, but also because they are thermally more stable,” according to the group.

It further noted that the amount of UV radiation and temperature play “a synergistic action in causing PV module degradation and have different influences on the structural integrity” of the polymers used for encapsulation.

“Our results on the variations in the optical, chemical and structural characteristics of the materials and on the electrical performances of the mini-devices have demonstrated that the mini-device made with the TPO film presents a higher stability in the long-term behavior, compared to POE and EVA,” said Fiandra.

At present, further research is underway to evaluate the moisture permeability in mini-devices made with the new encapsulants, along with degradation effects on reliability and durability. The researchers are also working on improving the efficiency of solar PV modules by using functionalized encapsulants with light downshifting properties, according to Fiandra.