“These projects are interesting and we observe them very closely.” But Luc also said his company currently focuses on using biomass to improve its CO2 balance, because making fuels with electrolysis is “not easy”.

Many deep-pocketed oil companies are on the lookout for new business models to secure their long-term survival in a decarbonising world. Oil major Shell caused a stir in Germany’s energy transition business community by taking over home battery start-up Sonnen earlier this year.

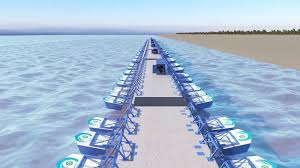

The production of “green hydrogen” with renewable power using electrolysis has lately become a hot topic in German industry, and a whole range of projects are dedicated to the development of the technology. For example, steelmaker Salzgitter has developed a “technically feasible but not economically viable” concept to replace the fossil fuels used in conventional steelmaking with a gradually rising share of renewable hydrogen made with electrolysis technology provided by start-up Sunfire. Sunfire says it plans additional projects to make synthetic fuels in cooperation with Swiss start-up Climeworks and Rotterdam The Hague Airport. Marking “groundbreaking progress”, a German pilot project has also made kerosene using concentrated sunlight, water and CO2 for the first time, according to the German Aerospace Center (DLR), which is a partner in the SUN-to-LIQUID project and also operates the Institute of Solar Research.

Luc also said the development of hydrogen fuel cell cars advances much slower than expected because carmakers currently focus on battery-electric vehicles. With regard to heavy duty vehicles, Luc said his company perceived a trend to power them with natural gas. This is why we will equip more and more petrol stations for trucks with gas propulsion in the months to come.