“Producing an operating version of a large-scale panel is a major milestone in the development of our pilot plant,” Tim Young, CEO of HyperSolar, said in a statement on Dec. 16. “We have confidence that this achievement, together with our work with engineers, will effectively lead us to manufacture high-quality, full-scale hydrogen panels for inclusion in our pilot plant.”

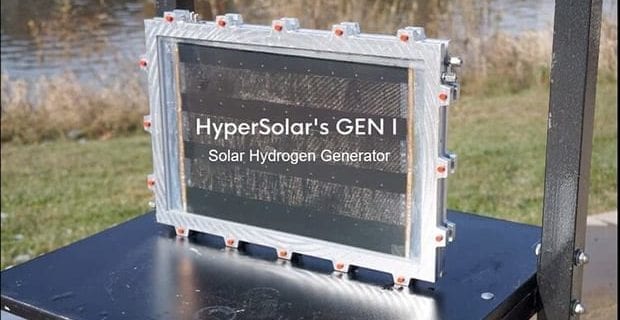

In June, the Santa Barbara, California-based company extended a sponsored research agreement it had with the University of Iowa through May 31, 2020. Research efforts at the university are being led by Assistant Professor Dr. Syed Mubeen and HyperSolar CTO Dr. Joun Lee. Their research is focusing on finalizing commercial processes for GEN 1 deployment and further development of GEN 2 technology. GEN 2 involves nanoparticle hydrogen production panels that are expected to have a much higher solar-to-hydrogen efficiency than GEN 1 at a lower manufacturing cost.

“We are working with multiple companies to achieve a mass production strategy for protective coatings that will protect the thousands of cells to be deployed in the pilot plant,” Young said in a June statement. “University of Iowa’s record-breaking development work, as demonstrated in the 1,000 hours of continuous device operation with our GEN 1 Cells, has made it possible for us to take the company to the next level.”

Hydrogen Production

Although hydrogen is an abundant element on Earth, it is almost always found as part of another compound, such as water (H2O) or methane (CH4). Therefore, hydrogen must be separated from the compounds that contain it before it can be used in its purest form.

The majority of hydrogen used today is produced through natural gas reforming, also known as steam methane reforming (SMR). HyperSolar claims more than 99% of today’s hydrogen supply is produced by SMR. The company says, “hydrogen is the cleanest fuel in the world,” but “the most-prevalent production process is obviously brown.”

The U.S. Department of Energy explains the SMR process on its website. It says, “Synthesis gas, a mixture of hydrogen, carbon monoxide, and a small amount of carbon dioxide, is created by reacting natural gas with high-temperature steam. The carbon monoxide is reacted with water to produce additional hydrogen. This method is the cheapest, most efficient, and most common.”

A synthesis gas can also be created by reacting coal or biomass with high-temperature steam and oxygen in a pressurized gasifier, which is converted into gaseous components—a process called gasification. The resulting synthesis gas contains hydrogen and carbon monoxide, which is reacted with steam to separate the hydrogen.