Oak Ridge National Laboratory (ORNL) and five leading building equipment industries will collaborate to improve the energy performance of heating, air conditioning and ventilation systems and investigate climate-friendly alternative refrigerants.

Through collaborative research and development agreements, or CRADAs, scientists at the Department of Energy’s (DOE’s) only designated national user facility for buildings research – the Building Technologies Research and Integration Center (BTRIC) at ORNL – will conduct research and development with the National Automatic Merchandising Association, Taylor Commercial Foodservice, Emerson Climate Technologies, Enginuity Power Systems, and Baltimore Aircoil Company.

“CRADAs are among the U.S. Department of Energy’s chief instruments to connect the ingenuity of our national labs with industry’s leading companies to produce innovations at the scale we need to make a difference,” said David Nemtzow, building technologies office director, DOE Office of Energy Efficiency and Renewable Energy.

Improving the energy efficiency of buildings and equipment is a priority for DOE’s Building Technologies Office (BTO), because the 127 million buildings in the United States consume nearly 40 percent of the nation’s total energy at a cost of $415 billion annually, accounting for 36 percent of carbon emissions. BTO’s goal is to create marketable technologies and design approaches that address energy consumption in existing and new buildings to reduce the average energy use in all U.S. buildings by 30 percent by 2030.

“We are pleased to apply the expertise and capabilities of Oak Ridge National Laboratory to develop energy-saving technologies in collaboration with these industry leaders,” said Moe Khaleel, associate laboratory director for Energy and Environmental Sciences at ORNL. “These collaborations are just the beginning of what we anticipate being a record number of industry partnerships over the next year to develop breakthroughs for energy-efficient buildings and a more secure, resilient power grid.”

ORNL’s BTRIC facility, established in 1993, has 40,000 square feet of laboratory space dedicated to early-stage research and development in building technologies, with the goal of improving the energy efficiency and environmental compatibility of residential and commercial buildings by focusing on building envelopes, equipment, building systems integration, energy storage and grid-interactive efficient buildings, sensors, transactive controls, and data modeling and simulation.

“Oak Ridge National Laboratory excels at translating scientific discoveries into new technology partnerships with industry,” said Daniel R Simmons, assistant secretary for the Office of Energy Efficiency and Renewable Energy at the Department of Energy. “These collaborations drive new innovations that address challenges and speed deployment of technologies into the marketplace where they will have the greatest impact in saving energy and boosting the American economy.”

The industry CRADAs will focus on the following:

National Automatic Merchandising Association (NAMA) – Evaluating environmentally friendly refrigerants for vending machines in North America, mitigating leak risks, and assessing potential hazards including flammability.

“NAMA and the NAMA Foundation are collaborating with researchers at ORNL because they have the recognized expertise needed to assist owners and operators of vending machine, equipment manufacturers and distributors throughout North America with the use and production of equipment that safely and efficiently uses next generation refrigerants,” said Eric Dell, executive vice president, NAMA.

Taylor Commercial Foodservice – Developing climate-friendly refrigerants for food processing and dispensing machines in quick service restaurants and food retail.

“More than three million refrigerated food/beverage processing, dispensing, and vending machines in the U.S. consume up 70 percent of energy through the compressor,” said Stephen Wadle, senior project engineer, Taylor Commercial Foodservice. “By working with ORNL, we will be able to develop environmentally friendly refrigerant solutions that meet domestic and international expectations.”

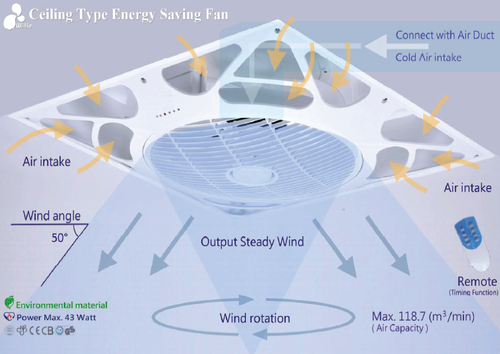

Emerson Climate Technologies – Accelerating the development of next-generation architecture for advanced heating, ventilation, air conditioning, and dehumidification coupled with energy storage and integrated water heating through a vapor compression system that utilizes long-term, climate-friendly refrigerants.

“By collaborating with ORNL on advanced technologies for HVAC systems, we’re developing a modular system with energy storage for grid-responsive capabilities,” said Hung Pham, director of integrated technologies, Emerson Climate Technologies. “We’ll be able to accomplish our objectives on an accelerated timeframe by working with the only user facility in the nation that has the technology and resources capable of developing this type of equipment.”

Enginuity Power Systems – Developing a prototype of a commercially ready micro combined heat and power, or mCHP, device with an internal combustion engine fueled by natural gas.

“ORNL’s BTRIC facility provides the knowledge needed in equipment modeling, design-for-manufacturing, equipment-grid interaction modeling, environmental chambers, and heat exchanger testing loops as well as a fully equipped research house that emulates real life occupancy,” said Jacques Beaudry-Losique, president, Enginuity Power Systems. “With this support, we will be able to launch the next generation of our mCHP device for large-scale commercialization.”

Baltimore Aircoil Company – Advancing next-generation heat exchanger technology that can be deployed in an evaporator cooling system, reducing the size of the system and decreasing energy and water usage by 30 percent.

“This collaboration will help us expedite the production of a novel heat exchanger technology that can operate in wet and dry or hybrid conditions,” said Michael Tenbrock, global technology R&D director, Baltimore Aircoil. “ORNL scientists will accelerate our understanding of emerging new materials and their potential for heat transfer applications.”

Collaborations with the five industries are anticipated to conclude within two or three years of each project’s implementation.