Cooperative Energy has commenced commercial operations on a new 22.7 MW natural gas-fired power plant in southern Mississippi.

The new plant, operated by the member-owned electric cooperative, will offer flexibility to extend the capacity of renewable generation in the future. It is also seen as critical to grid reliability due to the threat of hurricanes in the region, according to the company.

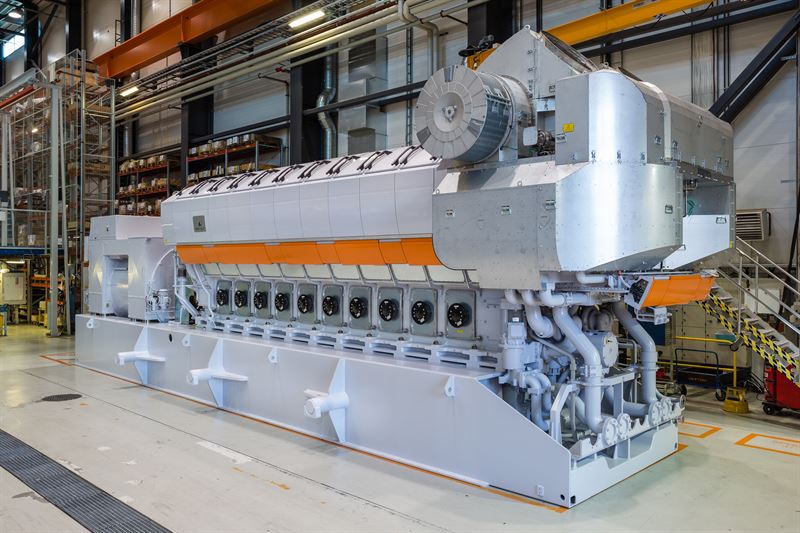

Wärtsilä led the engineering, procurement and construction (EPC) efforts on the Benndale, Mississippi power plant. Benndale has two Wärtsilä 31SG gas engines as the prime power generators.

“As a not-for-profit electric cooperative, our mission is to provide our members with electricity that is both reliable and economical,” Trey Cannon, director of generation for Cooperative Energy, said. “The Wärtsilä engines provide efficiency that is far greater than any of our simple cycle units, while also adding flexibility to our generation fleet. We greatly appreciated the competence and support that Wärtsilä has provided throughout this project.”

The 31SG is a reciprocating, 4-stroke engine which is touted as providing simple-cycle efficiency in excess of 50 per cent, compared with the 40 per cent level of many modern gas turbines, according to Wärtsilä. It also offers fast start capability to respond to changing load patterns with intermittent solar and wind energy on the grid.

The new engine also is a culmination of Wärtsilä’s vow to reduce the greenhouse gas emissions from its gas-fired engines 15 per cent below 2015 levels by this year.

“It is always exciting to see progress in action, and this next generation flexible power plant represents real energy sector progress in terms of efficiency and flexibility,” Toni Haarala, project manager at Wärtsilä, commented: “We have enjoyed an excellent relationship with Cooperative Energy, and it’s rewarding to see this plant now in full commercial operation.”

Cooperative Energy also signed up Wärtsilä to provide a 10-year service commitment. This covers engine maintenance, auxiliary equipment, asset diagnostics and response time guarantees.

The Benndale plant was designed in a way so it could be expanded in the future. Additional engines could be added by extending the engine hall.