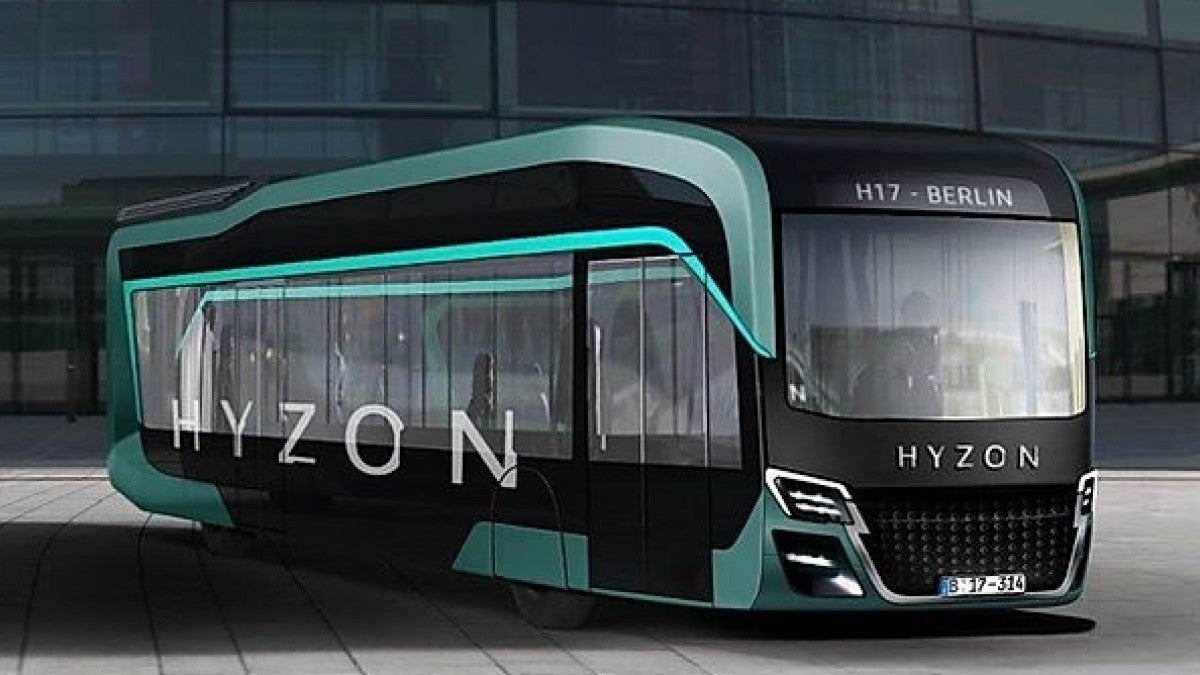

Hyzon Motors, a spin-off of Horizon Fuel Cell Technologies, was established in March. The New York-based company will specialize in fuel cell-powered heavy trucks, buses, and delivery vans. It will be the first US company offering commercial vehicles equipped with proton exchange membrane fuel cell systems that exceed 100 kW and are specifically designed for commercial vehicles.

Hyzon says it has a signed memorandum of understanding with an undisclosed company for the manufacture of 1,000 fuel cell-powered 40-foot single cab buses. The first 50 buses are scheduled for delivery within 12 months. The company says it can produce up to 10,000 buses and trucks a year and that it is now accepting orders. Starting later this year, Hyzon vehicles will be available with the industry leading 370 kW (500 horsepower) Horizon fuel cell.

George Gu is the CEO of Hyzon Motors. Previously he served as chairman of the board of Horizon Fuel Cell Technologies for 16 years. He says, “We have seen incredible growth in Asia in recent years at Horizon, and now with the experience gained from hundreds of trucks in commercial service, we aim to bring our technology to the roads of the world. Our Fuel Cell systems have already proven themselves, and we see an opportunity to help the world decarbonize transport much faster than people currently believe is possible.”

Hyzon is moving fast. This week it announced the establishment of a subsidiary in Australia.The assembly of fuel cell trucks and buses in Australia by Hyzon, working with strategic partners, is scheduled to begin in 2022 at the latest. “Green hydrogen investment plans for Australia are a lot more viable supplying into the local heavy vehicle market, as diesel displacement is a much higher value use for hydrogen than bulk export,” Hyzon Motors said in a statement.

“Governments and major corporations need to solidify plans to transition off diesel. It’s a match made in hydrogen heaven. Green hydrogen investment plans for Australia are a lot more viable supplying into the local heavy vehicle market, as diesel displacement is a much higher value use for hydrogen than bulk export. Governments and major corporations need to solidify plans to transition off diesel. It’s a match made in hydrogen heaven.”

Hydrogen powertrains have zero emissions, but where does the hydrogen come from? Much of the hydrogen commercially available today comes from fracked natural gas. The negative effects of fracking on the environment are well known. In fact, the well-to-wheel emissions of hydrogen from fracked gas are worse than those associated with digging and burning coal. Another way to make hydrogen is to hydrolyze it — which means splitting water into its component parts with electricity. That assumes there is an abundance of excess electricity available that does not have a higher and better use.

Hydrogen refueling stations can cost 10 times as much as an equivalent electric vehicle charging facility. Today, there are thousands of EV chargers, but only a handful of hydrogen fueling stations. The cost of building hydrogen refueling infrastructure will be significantly higher than doing the same for EV charging options.

Finally, hydrogen tends to cost more than electricity for an equal amount of energy. A fuel cell-powered vehicle may in fact cost less to operate than a diesel powered vehicle — diesel maintenance is expensive — but whether total operating costs are less than for an equivalent battery operated vehicle remains to be seen.

The place where fuel cells shine is moving heavy loads long distances with zero emissions. A fuel cell bus could theoretically go from New York to Chicago without refueling, which is something no battery-powered bus can do yet. Whether that is enough of an advantage to convince fleet operators to prefer fuel cell power over battery power is unknown. Hyzon thinks it has answers to the technical challenges of making fuel cell-powered heavy vehicles and doing so profitably. “We’ll see,” said the Zen master.