The company on May 20 said the plant will feature SGH2’s technology that uses recycled mixed paper waste to produce “greener than green” hydrogen. SGH2 said its process “reduces carbon emissions by two to three times more than green hydrogen produced using electrolysis and renewable energy, and is five to seven times cheaper.” The deal with Lancaster, first announced Tuesday, noted that SGH2 makes hydrogen with a plasma heating technology, originally developed for NASA, that will disintegrate recyclable materials at temperatures as high as 7,000F.

The company said its green hydrogen is cost competitive with so-called “gray” hydrogen produced from fossil fuels like natural gas, which comprises most of the hydrogen used in the U.S. The company’s process has no commercial track record, and Solena Group said it does not yet have financing for the proposed $55 million facility. The company is among many worldwide working to develop ways to produce hydrogen in a cost-effective manner.

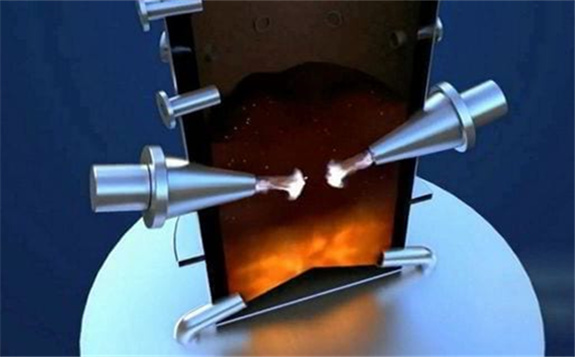

Plasma torches are shown inside SGH2’s gasification chamber. The torches heat waste materials to temperatures of up to 4,000C, turning solids to gases.

Solena Group in 2015 attempted to build a commercial facility to produce jet fuel at a plant in the UK. The project, a joint venture with British Airways, was dropped after oil prices crashed.

“Green hydrogen” has been touted as a replacement for natural gas for heating and cooking. The Los Angeles Department of Water and Power last year said it would attempt to build what would be the world’s first hydrogen-fueled power plant.

City Will Co-Own Facility

The City of Lancaster will co-own the production facility, according to a memorandum of understanding between the city and SGH2. The plant will produce up to 11,000 kilograms of green hydrogen per day, 3.8 million kilograms per year—nearly three times more than any other green hydrogen facility, built or under construction, anywhere in the world, according to the company—and will process 42,000 tons of waste annually.

The SGH2 process was developed by NASA scientist Dr. Salvador Camacho and SGH2 CEO Dr. Robert T. Do, a biophysicist and physician. The company’s technology gasifies any kind of waste, including plastic, paper, rubber, and textiles. The company said the technology has been “vetted and validated, technically and financially, by leading global institutions including the U.S. Export-Import Bank, Barclays and Deutsche Bank, and Shell New Energies’ gasification experts.”

Do co-founded his company more than 30 years ago along with Camacho, a former NASA engineer. Camacho helped the space agency develop a plasma heating technique, designed to generate temperatures at a level that would simulate a spacecraft’s re-entry to Earth’s atmosphere. The technology was used to test the heat shields to protect U.S. space capsules as they returned to Earth.

“The world needs some good news right now, and we have it. Affordable, mass-produced, reliable green hydrogen is the missing link needed to decarbonize the world,” said Do. “We provide that link. We are the only company in the world delivering green hydrogen that is cost competitive with the cheapest, dirtiest hydrogen made from coal and gas, and much less expensive than other green hydrogen. Our technology can scale quickly and produce fuel 24/7, year-round.”

“As the world, and our city, cope with the coronavirus crisis, we are looking for ways to ensure a better future. We know a circular economy with renewable energy is the path, and we have positioned ourselves to be the alternative energy capital of the world,” said Lancaster Mayor R. Rex Parris as the project was announced. “This is game-changing technology. It not only solves our air quality and climate challenges by producing pollution free hydrogen, it also solves our plastics and waste problems by turning them into green hydrogen and does it clean and at costs far lower than any other green hydrogen producer.”

Groundbreaking Set for 2021

The plant is expected to be built on five acres in an industrial area of Lancaster. The facility will employ about 35 workers once operational, and is expected to provide more than 600 jobs during construction. SGH2 said it expects to break ground in early 2021, with start-up and commissioning in late 2022, and full operations scheduled in early 2023.

City officials said Lancaster will guarantee a supply of recyclables for the facility. The city said it will save between $50 to $75 per ton in landfill costs, and also said several hydrogen refueling stations in California are negotiating to purchase the plant’s supply.

Hydrogen has been touted as a key to fueling heavy industrial sectors such as transport, steel-making, and the cement industry. It also can provide long-term storage for renewable energy output. It also can reduce, and possibly replace, natural gas in many applications.

“Hydrogen is the emerging solution for hard-to-decarbonize sectors like the cement industry,” said Lawrie Evans, a technical expert in the cement industry, and former director of LafargeHolcim, the world’s largest cement manufacturer. “SGH2’s solution—to produce green hydrogen and bio-syngas from the gasification of biomass and biogenic waste using its SPEG process—can be a cost competitive solution to provide the high quality heat required in our industry, and replace or reduce the usage of coal and coke.”

Replacing Fossil Fuels, Reducing Emissions

clean hydrogen could reduce global greenhouse gas emissions from industry and fossil fuels by as much as 34%.

Dr. Hanna Breunig, a research scientist in the Sustainable Energy Systems group in the Energy Analysis and Environmental Impacts division of the Lawrence Berkeley National Laboratory, in a news release said, “Countries around the world are waking up to the critical role green hydrogen can play in increasing energy security and lowering greenhouse gas emissions. But, until now, it has been too expensive to adopt at scale.”

The project is being developed by a consortium of global companies in addition to SGH2 and the City of Lancaster, including the Berkeley Lab, the University of California-Berkeley, Fluor, Thermosolv, Integrity Engineers, Millenium, HyetHydrogen, and Hexagon. Fluor is providing front-end engineering and design for the facility, with its subsidiary Stork providing maintenance services.

Technology Gasifies Biogenic Waste

SGH2’s “greener than green” claim comes because in addition to producing carbon-free hydrogen, the company’s Solena Plasma Enhanced Gasification (SPEG) technology gasifies biogenic waste materials, and uses no externally sourced energy. The company said that Berkeley Lab in a preliminary lifecycle carbon analysis found “that for every ton of hydrogen produced, SPEG technology reduces emissions by 23 to 31 tons of carbon dioxide equivalent, which is 13 to 19 tons more carbon dioxide avoided per ton than any other green hydrogen process. And SGH2 hydrogen is five to seven times cheaper than other green hydrogen.”

The company’s gasification technology uses a very-high-temperature (3,500C to 4,000C) plasma-enhanced thermal catalytic conversion process optimized with oxygen-enriched gas. The process “results in the complete molecular dissociation of all hydrocarbons and the production of a very high quality, hydrogen-rich bio-syngas free of tar, soot and heavy metals,” the company said. “No other hydrogen-production technology can eliminate plastic as cleanly and as efficiently, if plastics are used or mixed in the feedstocks.”

Other types of hydrogen production, the so-called blue, gray, and brown hydrogen, use mostly natural gas or coal, or low-temperature gasification (<2,000C), which produces synthetic gas with “toxic tars and low volume of hydrogen,” the company said. Other green hydrogen producers use electrolysis that uses large amounts of renewable energy and deionized water, which is considered green if it comes from 100% renewable power. The offshore wind industry is looking at becoming a major player in the production of hydrogen from wind power, via electrolysis from water, as a direct substitute for hydrogen produced from fossil fuels.

Taco de Haan, president of Stork, said, “As part of the design team we look forward to assisting in the optimization of plant design with reliability-based maintenance principles followed by delivering the actual plant operations and maintenance services. We are proud to be a part of this partnership as its objectives are so well aligned with Storks’ sustainability agenda and our commitment to the global energy transition.”

Similar Projects in Several Countries

SGH2 is in negotiations to launch similar projects in several countries, including Australia, Brazil, China, France, Saudi Arabia, Ukraine, Greece, Japan, South Korea, Poland, Turkey, Russia, and Malaysia. The company’s stacked modular design is built to be rapidly scaled, and is not dependent on weather conditions. It also does not require as much land as solar- and wind-based projects.

Do said his company’s facilities will be “small, distributed plants,” and said the company can easily build multiple units at one location.

Tan Sri Halim Mohammad, executive chairman of the Halim Mazmin Group and owner of one of Malaysia’s largest shipping companies, noted that “Malaysia has a tremendous supply of biomass waste, which, if not used, would be burned. Using SGH2’s technology, we can convert this biomass waste to green hydrogen economically for use in land transport and shipping, which will help reduce dependency on oil and gas.”

BNEF’s analysis has said that costs for green hydrogen are forecast to fall to $2 per kilogram by 2030 in Western Europe and India. SGH2 said it already would be able to produce green hydrogen at that cost.