Scientists at the US Department of Energy’s Argonne National Laboratory have developed platinum-free fuel cell catalysts that can be used for cheaper hydrogen fuel cell production.

Commercially available hydrogen fuel cells currently rely on the oxygen reduction reaction (ORR), which splits oxygen molecules into oxygen ions and combines then with protons to form water.

The reaction is part of the overall fuel cell process that coverts hydrogen and oxygen in air into water and electricity. The ORR is a relatively slow reaction, limiting fuel cell efficiency and requiring a large amount of platinum catalyst.

“Currently, the oxygen reduction reaction is facilitated by platinum alloy catalysts, which are the most expensive component of the fuel cell electrodes,” said Deborah Myers, Senior Chemist and Leader of the Hydrogen and Fuel Cell Materials group.

“Widespread, sustainable commercialisation of fuel cell electric vehicles requires either a dramatic reduction in the amount of platinum required or the replacement of platinum catalysts with those made of earth-abundant, inexpensive materials like iron.”

The most promising platinum-free catalyst for use in the ORR is based on iron, nitrogen and carbon. To produce the catalyst, scientists mix precursors containing the tree elements and heat them between 900-1100°C in a process call pyrolysis.

After pyrolysis, the iron atom in the material are bonded with four nitrogen atoms and imbedded in a plane of graphene, a one-atom thick layer of carbon. Each of the iron atoms constitutes an active site, or a site at with the ORR can occur.

“The mechanisms by which the active sites are formed during pyrolysis are still very mysterious. We observed the process in real time at the atomic scale to gain understanding and to inform the design of better-performing catalysts,” explains Myers.

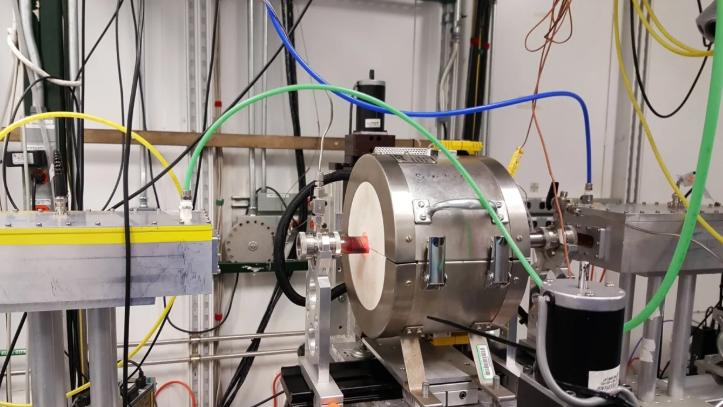

The researchers conducted in situ X-ray absorption spectroscopy at the Materials Research Collaborative Access Team at Argonne’s Advanced Photon Source (APS), a DOE of Science User Facility, to uncover the behaviour of the material at the atomic scale during pyrolysis.

Whilst conducting the experiment, the scientists found that during the pyrolysis of the iron, nitrogen and carbon precursor mixture, the nitrogen-graphene sites are formed first, and then gaseous iron atoms insert themselves into these sites.

They also found that they can produce a higher density of active sites in the catalyst by inserting nitrogen into the carbon first, using a technique called doping, and then introducing iron to the system during pyrolysis, as opposed to heating all three components together.

During this process, the scientists place the nitrogen-doped carbon in the furnace, and gaseous iron atoms insert themselves in vacancies at the centre of groups of four nitrogen atoms, forming active sites.

This approach avoids clustering and burial of iron atoms in the bulk of the carbon, increasing the number of active sites on the graphene surface.

The study was a part of a larger project funded by the DOE Fuel Cell Technologies Office, called the Electrocatalysis Consortium (ElectroCat), aimed specifically at driving development of platinum-free catalysts for fuel cells.