Hydrogen researchers at Graz University of Technology (Austria), together with the Graz-based start-up Rouge H2 Engineering, have developed a cost-effective process for the decentralized production of high-purity hydrogen using chemical looping.

Currently, hydrogen is mainly produced centrally from fossil resources and compressed or liquefied in an expensive and energy-intensive process in order to be able to supply it to filling stations. Additionally, expensive infrastructure with high investment costs is needed there to store large quantities of hydrogen.

The Fuel Cells and Hydrogen Systems Working Group at TU Graz’s Institute of Chemical Engineering and Environmental Technology has been looking for ways to make hydrogen production more attractive. As part of the HyStORM (Hydrogen Storage via Oxidation and Reduction of Metals) research project, the team led by working group head Viktor Hacker developed a chemical-looping hydrogen method for decentralized and climate-neutral hydrogen production.

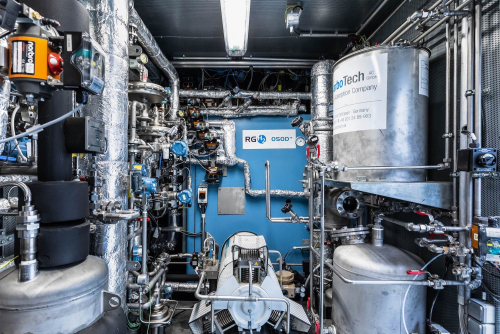

The research resulted in a compact and space-saving on-site, on-demand (OSOD) system for filling stations and energy plants and is being developed and distributed by the Graz-based start-up Rouge H2 Engineering.

The OSOD system is a hydrogen generator with integrated storage device in one system. Hydrogen is produced by converting biogas, biomass or natural gas into a syngas. The provided energy is then stored by means of a redox process (reduction-oxidation process) in a metal oxide, which can be stored and transported without any losses or safety risks.

The subsequent demand-oriented production of hydrogen is achieved by feeding water into the system. The iron-based material is charged with steam and high-purity hydrogen is released.

This process also makes the system interesting for smaller applications.

For this reason, the OSOD system is freely scalable and is particularly suitable for decentralized applications with low feed-in rates in laboratories and smaller industrial systems as well as larger decentralized units such as hydrogen filling stations or hydrogen production from biogas.

In addition to the provision of high purity hydrogen, Gernot Voitic, lead project manager of R&D at Rouge H2 Engineering, points out that the OSOD system can switch to standby mode in the case of low demand and resume hydrogen production at any time if required.

Rouge H2 Engineering and TU Graz researchers are already focusing on the next step. At present, the system is still operated on an industrial scale with natural gas. The working group now wants to make it usable for biogas, biomass and other regionally available raw materials. Biogas plants, for example, could thus become even more competitive in the future and, instead of electricity, also produce green hydrogen, which could be used for sustainable mobility concepts.

The HyStORM research project is anchored in the Field of Expertise “Mobility & Production” at TU Graz, one of the five strategic research foci of the university.