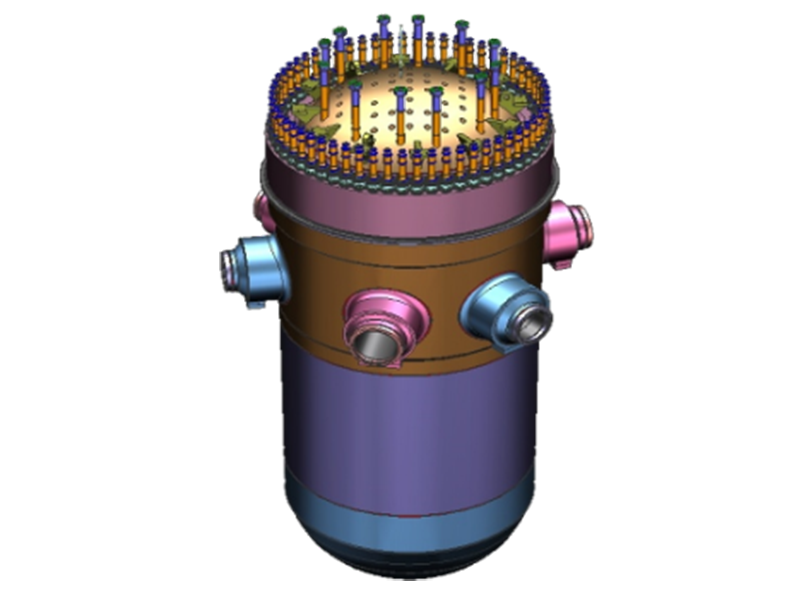

The reactor pressure vessel is the heart equipment in the nuclear island of the nuclear power plant. It is mainly used to hold the reactor core. It is a cylindrical vessel equipment connected by vertical large open flange bolts. It is mainly composed of reactor vessel, integrated head assembly, and fastening seals.

| Company name | Yantai Taihai Manuel Nuclear Power Equipment Co., Ltd | ||

| Contacts | Steven Chu | TEL | 86-0535-3725998 |

| FAX | 86-0535-3725998 | [email protected] | |

| Address | No. 2, Xiulin Road, Yantai Economic and Technological Development Zone | ||

| Company profile | |||

|

Yantai Taihai Manure Nuclear Power Equipment Co., Ltd. (hereinafter referred to as "THM") is a wholly-owned subsidiary of Taihai Manure Nuclear Power Equipment Co., Ltd., an A-share listed company. Its predecessor is Manuel (Yantai) Industry Co., Ltd., which was founded in 1994. The company has 1068 employees and total assets of 4.1 billion yuan. The company is a specialized nuclear power equipment manufacturing enterprise that is committed to developing and manufacturing key materials for nuclear power plants, core components of key equipment, metal equipment and pipeline equipment (such as main pipes, surge pipes, main steam super pipes, special alloy large-diameter thin-wall pipelines) and other products. THM has established a complete quality assurance system, and has successively passed a series of quality management system certifications such as ISO9001 quality management system, ISO14001 environmental management system, GB/T28001 occupational health and safety management system. According to the requirements of HAF, a complete nuclear quality assurance system has been established and the Civil Nuclear Safety Machinery and Equipment Manufacturing License has been obtained; It has passed the American Society of Mechanical Engineers (ASME) certification and holds ASME NPT, NS and U steel seal certificates. THM is equipped with more advanced production equipment in the world, such as smelting, electroslag remelting, casting, forging (free forging, open die forging, external forging), reverse extrusion, heat treatment, machining, welding, etc. THM has formed the second generation of improved cast main pipes, the third generation of nuclear power forged main pipes, the surge pipes, the fourth generation of nuclear power large-diameter thin-wall forged pressure pipes, the small reactor nuclear island main vessels, the integrated main steam super pipes, the nuclear primary castings (main pump casing, squib valve body, main equipment support), the nuclear primary forgings (reactor pressure vessels, evaporators, pressurizers, main pumps, reactor internals), mechanical penetrations Batch supply capacity of fuel assembly upper and lower pipe seats and other products. Up to now, the company has provided nearly 40 reactor units at home and abroad with primary circuit main equipment, structural components, nuclear primary components and other products. Applicable products for nuclear power The second generation of improved cast main pipe, the third generation of nuclear power forged main pipe, the surge pipe, the fourth generation of nuclear power large-diameter thin-wall forged pressure pipe, the main vessel of the small reactor nuclear island, the integrated main steam super pipe, the nuclear primary casting, the nuclear primary forging, the mechanical penetration, the upper and lower pipe seats of the fuel assembly. |

|||